Nicotra Forward Curved Centrifugal Fan ADH 630 R

Nicotra Forward Curved Centrifugal Fan ADH 630 R Specification

- Usage & Applications

- HVAC Systems, Industrial Ventilation, Air Handling Units

- Measurement

- Air Flow Rate

- Automation Grade

- Semi-automatic

- Air Flow

- 8500-9000 m/h

- Orientation

- Horizontal Mounting

- Instruments Type

- Industrial Fan

- Efficiency

- High Efficiency

- Power Source

- Electric

- Temperature

- Ambient to 60C

- Product Type

- Forward Curved Centrifugal Fan

- Material

- Galvanized Steel

- Cooling System

- Air Cooling

- Noise Level

- Less than 85 dB(A)

- Processing Time

- Continuous

- Capacity

- Approx. 8500-9000 m/h

- Voltage

- 380-415 V

- Weight

- Approx. 79 kg

- Dimension (L*W*H)

- 820 x 830 x 770 mm

- Surface

- Powder Coated

Nicotra Forward Curved Centrifugal Fan ADH 630 R Trade Information

- Minimum Order Quantity

- 1 Piece

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Main Domestic Market

- All India

About Nicotra Forward Curved Centrifugal Fan ADH 630 R

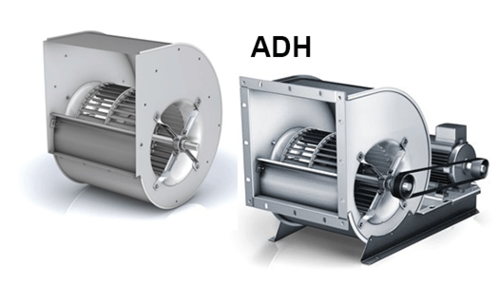

Nicotra Forward Curved Centrifugal Fan ADH 630 R

Product Benefits

High Efficiency Airflow Solution

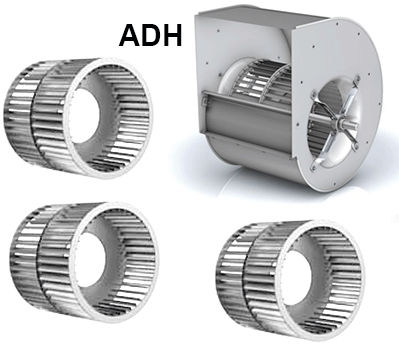

The ADH 630 R is engineered to ensure maximum airflow efficiency for industrial ventilation and HVAC systems. Its forward curved, double inlet impeller balances performance with energy savings, making it an ideal solution when consistent volume and pressure are needed in tough operating conditions. The direct-drive, three-phase design facilitates reliable operation and easy integration.

Robust Construction and Design

Manufactured from galvanized steel with a powder-coated surface, this centrifugal fan boasts long-lasting durability even in demanding environments. With insulation class F and IP54 protection, it is designed to operate at a maximum altitude of 1000 meters and handle ambient temperatures up to 60C, ensuring safety and longevity.

FAQs of Nicotra Forward Curved Centrifugal Fan ADH 630 R:

Q: How can the Nicotra ADH 630 R Centrifugal Fan be integrated into HVAC systems?

A: The Nicotra ADH 630 R is specifically designed for seamless integration into HVAC systems and air handling units due to its direct drive, three-phase operation, horizontal mounting, and flanged connection type. Its high airflow rate and static pressure allow it to support ventilation needs in both commercial and industrial spaces.Q: What are the main benefits of choosing the ADH 630 R fan for industrial ventilation?

A: This model provides high airflow (approx. 8500-9000 m/h) with impressive energy efficiency, low noise levels (below 85 dB(A)), and robust construction. Its forward-curved, double inlet impeller suits applications demanding consistent, high-volume air movement, while the galvanized steel housing ensures durability.Q: When is routine maintenance required for the ADH 630 R fan?

A: Maintenance requirements depend on operational conditions, but it is recommended to check the fan periodically for dust accumulation, mechanical wear, and secure connections, especially when operating continuously in humid or dusty environments.Q: Where is the fan best installed for maximum efficiency and safety?

A: Ideal locations for installation include mechanical rooms, HVAC chambers, or industrial ventilation spaces where airflow is critical. The horizontal mounting orientation and flanged connection facilitate secure, leak-proof installation, enhancing efficiency and safety.Q: What is the process for connecting and powering the ADH 630 R fan?

A: The fan connects easily to three-phase electrical supplies (380-415 V) using a direct drive mechanism. After securing the unit in the desired orientation, ensure all electrical and flanged connections are tight and verify that the systems voltage and frequency match the fans specifications.Q: Can the ADH 630 R operate in high humidity or elevated temperature environments?

A: Yes, this model is rated to function in environments with relative humidity up to 95% (non-condensing) and ambient temperatures up to 60C, making it suitable for a variety of challenging industrial conditions.Q: What applications are most suitable for the ADH 630 R Centrifugal Fan?

A: This fan excels in applications like HVAC systems, industrial ventilation, and air handling units where steady airflow, high efficiency, and robust performance are essential.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Series ADH Nicotra Forward Curved Centrifugal Fan Category

Nicotra Forward Curved Centrifugal Fan ADH 500 R

Price 40000 INR

Minimum Order Quantity : 1 Piece

Material : Galvanized Steel

Air Flow : Up to 4900 m/h

Product Type : Forward Curved Centrifugal Fan

Noise Level : < 80 dB

Nicotra Forward Curved Centrifugal Fan ADH 280 R

Price 20500 INR

Minimum Order Quantity : 1 Piece

Material : Galvanized Steel

Air Flow : Up to 2500 m/h

Product Type : Forward Curved Centrifugal Fan

Noise Level : 70 dB(A)

Nicotra Forward Curved Centrifugal Fan ADH 400 R

Price 29000 INR

Minimum Order Quantity : 1 Piece

Material : Galvanized Steel

Air Flow : 3500 m/h (at nominal speed)

Product Type : Forward Curved Centrifugal Fan

Noise Level : Below 82 dB(A)

Nicotra Forward Curved Centrifugal Fan ADH 355 R

Price 25000 INR

Minimum Order Quantity : 1 Piece

Material : Galvanized Steel

Air Flow : 5000 m/h

Product Type : Forward Curved Centrifugal Fan

Noise Level : 75 dB(A)

Send Inquiry

Send Inquiry