Mist Eliminator

Mist Eliminator Specification

- Air Flow

- 1200-3000 m/hr

- Material

- Stainless Steel, Polypropylene

- Motor

- 0.5 HP

- Application

- Air pollution control, Industrial exhaust, Fume extraction

- Condition

- New

- Type

- Vertical Mist Eliminator

- Dimension (L*W*H)

- 900 x 900 x 1600 mm

- Power Supply

- Single Phase AC

- Voltage

- 220-240 V

- Cooling Type

- Air & Water cooled

- Nozzle Material

- Polypropylene

- Water Flowing Rate

- 70 L/min

- Water Pump Motor

- 0.5 HP

- Noise Control

- Below 75 dB

About Mist Eliminator

Mist EliminatorWe offer a wide range of Mist Eliminator, that are made of FRP/PVC, the eliminator is used to reduce water losses due to entrainment of moisture drops in the air stream. We also offer these as per our customers' requirements & specifications.

High-Efficiency Mist Removal

Achieve superior air quality management with up to 99% mist removal. Engineered for demanding environments, this mist eliminator efficiently captures airborne droplets, controlling industrial emissions and enhancing air purity for workers and machinery alike.

User-Friendly Installation and Maintenance

Installation is straightforward with the floor-mounted vertical configuration. Both maintenance and cleaning are hassle-free, requiring minimal intervention, thanks to the easily accessible design and durable construction from stainless steel and polypropylene.

Versatile Applications and Reliable Operation

Designed for air pollution control, fume extraction, and exhaust purification, this mist eliminator operates effectively within a temperature range up to 90C. Its sturdy build ensures consistent performance, maintaining safety standards and regulatory compliance across various industrial settings.

FAQs of Mist Eliminator:

Q: How does the mist eliminator function in air pollution control applications?

A: The mist eliminator uses a combination of air and water cooling, along with specialized nozzles, to efficiently remove up to 99% of mist and fine droplets from industrial exhaust streams, improving overall air quality and reducing emissions.Q: What is involved in the installation process for this mist eliminator?

A: Installation is simple as the unit is floor mounted. Ensure a single-phase AC power supply (220240 V) is available and that the units inlet/outlet (150 mm) aligns with existing ductwork. Detailed installation guidelines are provided by the manufacturer.Q: When should the mist eliminator be cleaned or maintained?

A: Thanks to its low maintenance design, the mist eliminator requires minimal cleaning. Regular visual inspections and periodic rinsing of internal components, as recommended in the user manual, will help maintain peak efficiency.Q: Where is this mist eliminator typically used?

A: This model is ideal for industrial settings, including factories and plants, for applications such as air pollution control, fume extraction, and exhaust gas cleaning. Its construction withstands demanding environments found in various sectors across India.Q: What benefits does the mist eliminator offer over traditional options?

A: Compared to standard solutions, this unit offers superior mist removal efficiency, low noise levels (below 75 dB), and reduced upkeep. Its easy-clean design and robust materials ensure longevity and operational cost savings.Q: How can users ensure the optimal operation of the mist eliminator?

A: Optimal performance is achieved by maintaining air flow rates between 12003000 m/hr and water flow at approximately 70 L/min, alongside regular inspections to confirm the continued integrity of the nozzles and motor.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

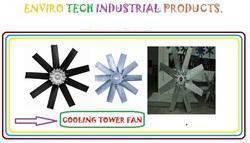

More Products in Cooling Tower Parts Manufacturers Wholesalers Category

Cooling Tower Sprinkler with Distribution Pipe

Condition : New

Material : Other , Aluminum Alloy Sprinkler Head, Mild Steel/HDPE Distribution Pipe

Type : Rotary Sprinkler with Pipe

Application : Industrial Cooling Towers, HVAC, power plants, process industries

Cooling Type : Water Evaporative

Dimension (L*W*H) : Customized as per tower design

cooling-tower- sprinkler-with- distribution-pipe

Condition : New

Material : Other , Aluminium/ABS plastic/FRP (Sprinkler Head), PVC/FRP (Distribution Pipe)

Type : Sprinkler with Distribution Pipe

Application : Cooling towers industrial and HVAC

Cooling Type : Water Cooling (Evaporative)

Dimension (L*W*H) : Varies by tower design; customized sizes available

Anti-corrosive Cooling Tower Fan Hub

Condition : New

Material : Other , Anticorrosive alloy

Type : Fan hub for cooling towers

Application : Cooling towers in industrial applications

Cooling Type : Air cooling

Dimension (L*W*H) : Varies depending on model

Send Inquiry

Send Inquiry