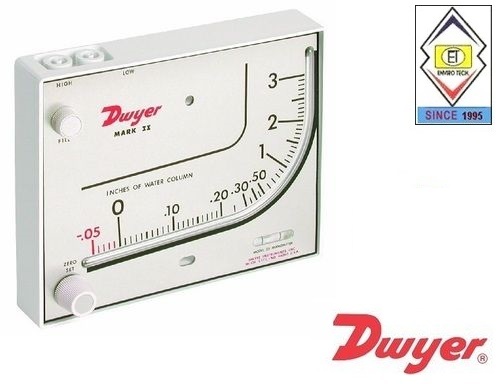

Mark II Model 40-1 Dwyer Manometer Range .1-0-1.0 Inches w.c

Mark II Model 40-1 Dwyer Manometer Range .1-0-1.0 Inches w.c Specification

- Outer Size

- 146 mm x 25 mm x 155 mm approx.

- Seal Material

- PVC rubber end seals

- Grade

- Industrial

- Sensor Type

- Liquid Column Differential

- Display

- Analog Scale

- Material

- High-Impact Acrylic

- Dial Material

- Printed Scale

- Processing Type

- Molded Acrylic Body

- Mount Type

- Wall or Panel Mount

- Scale Range

- .1-0-1.0 Inches w.c.

- Accuracy

- 1% of Full Scale

- Finishing

- Clear Acrylic Front

- Measure Pressure Of

- Air and Gas (Low Differential)

- Accessories

- Flexible Vinyl Tubing, Plastic Bottle of Red Gauge Fluid, Plastic Carry Case

Mark II Model 40-1 Dwyer Manometer Range .1-0-1.0 Inches w.c Trade Information

- Minimum Order Quantity

- 12 Pieces

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA), Telegraphic Transfer (T/T), Paypal, Cash in Advance (CID), Cheque

- Main Export Market(s)

- Australia, South America, Western Europe, Africa, Asia, Central America, Eastern Europe, North America

- Main Domestic Market

- Dadra and Nagar Haveli, Himachal Pradesh, Meghalaya, Andaman and Nicobar Islands, Pondicherry, Uttarakhand, Daman and Diu, Lakshadweep, Nagaland, South India, East India, Andhra Pradesh, Assam, Arunachal Pradesh, Bihar, Chandigarh, Delhi, Gujarat, Goa, Haryana, Jammu and Kashmir, Jharkhand, Madhya Pradesh, Maharashtra, Mizoram, Manipur, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, All India, Karnataka, North India, Kerala, Central India, Odisha, Uttar Pradesh, West India, Chhattisgarh

About Mark II Model 40-1 Dwyer Manometer Range .1-0-1.0 Inches w.c

Mark II Model 40-1 Dwyer Manometer Range .1-0-1.0 Inches w.c

Mark II Manometers are economically priced, compact and available in both stationary and portable configurations. The portable stand is a standard feature on Model 40. Construction is simple with virtually indestructible molded white styrene-acrylonitrile housing, indicating tube and fluid wells, molded ABS knobs and zero adjust plunger, shock mounted glass level vial and leak proof O ring seals. Greater protection is provided by float operated overflow traps in the Model 40. Scales are lithograph printed on aluminum and epoxy coated.

Mark II Manometers can be mounted on any vertical surface with the two mounting screws provided. A built-in spirit level simplifies leveling before mounting screws are tightened. Simply fill the reservoir, adjust fluid level to zero, connect the tubing, and the gage is ready for operation.

Included with each

Mark II Manometer

are two tubing connectors for 1/8" pipe or sheet metal ducts, two mounting screws, 3/4 ounce bottle of indicating fluid, red and green pointer flags and complete instructions. The Model 40 contains two 4-1/2 foot lengths of clear plastic tubing, a plastic swing-out stand and leveling screw for portable operation. It also features convenient rapid shutoff pressure connections and integral overpressure safety traps.

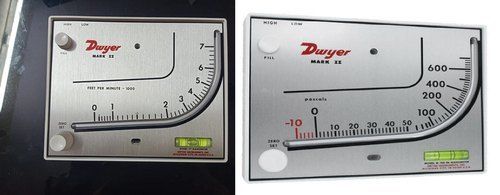

| Model | Range | Fluid Used |

| Mark II 40-1 | .1-0-1.0 in w.c. | Red oil, .826 s.g. |

| Mark II 40-25mm | 0-26 mm w.c | Red oil, .826 s.g. |

| Mark II 40-250PA | 10-0-250 Pa | Red oil, .826 s.g. |

| Mark II 41-2 | .2-0-2.4 in w.c. | Blue oil, 1.91 s.g. |

| Mark II 41-60mm | 0-60 mm w.c. | Blue oil, 1.91 s.g. |

| Mark II 41-600PA | 20-0-600 Pa | Blue oil, 1.91 s.g. |

| Mark II 40-1-AV* | 0-1.1 in w.c. | Red oil, .826 s.g. |

| Mark II 40-250PA-AV* | 0-260 Pa | Red oil, .826 s.g. |

| Mark II 41-2-AV* | 0-2.5 in wc. | Blue oil, 1.91 s.g. |

Versatile Pressure Measurement

Mark II Model 40-1 is engineered to measure low differential pressure of air and gas with high accuracy. Its inclined and vertical scale design ensures clear readings, making it suitable for applications like HVAC system analysis, filter performance checks, and static pressure determination.

Robust Construction and Accessories

Featuring a molded acrylic body and high-impact polystyrene case, the manometer ensures durability while maintaining a lightweight profile. Included accessories, such as flexible tubing, red gauge oil, and a portable carry case, enhance its utility for both field and laboratory settings.

Simple Installation and Operation

Install the Mark II Model 40-1 easily on a wall or panel with nozzle tube connections for hassle-free setup. The analog scale provides direct readings, while the zero adjustment ensures measurement accuracy, streamlining pressure monitoring processes for HVAC professionals.

FAQs of Mark II Model 40-1 Dwyer Manometer Range .1-0-1.0 Inches w.c:

Q: How do I install the Mark II Model 40-1 Dwyer Manometer for pressure measurement?

A: The manometer can be wall or panel mounted using its integrated fittings. Attach the provided flexible vinyl tubing to the nozzle fittings, ensuring they connect securely to the pressure sources you wish to monitor. Refer to the included instructions for proper setup.Q: What types of pressure can the Mark II Model 40-1 measure?

A: This manometer is designed to measure low differential pressures of air and gas within a range of .1 to 1.0 inches w.c. It is ideal for static pressure monitoring in HVAC systems and filter performance evaluations.Q: When should the red gauge oil be refilled in the manometer?

A: Check the fluid level periodically, especially after frequent usage. If the fluid level drops below the minimum required line or readings become inconsistent, refill using the supplied bottle of red gauge fluid to maintain accurate measurements.Q: Where is the Mark II Model 40-1 commonly used?

A: It is utilized in industrial environments, HVAC installations, laboratories, and anywhere low differential air and gas pressure monitoring is essential. Its portability and robust design make it suitable for both fieldwork and stationary settings.Q: What is the benefit of using the included zero adjustment feature?

A: The zero adjustment allows users to calibrate the manometer to ensure that measurements start from an accurate baseline, increasing the reliability of pressure readings and minimizing error due to environmental changes.Q: How does the analog scale display facilitate pressure monitoring?

A: The clear, printed scale on the acrylic front provides direct and easy-to-read results. This analog interface helps technicians quickly assess pressure levels without the need for electronic processing or interpretation.Q: Is the Mark II Model 40-1 compliant with safety and environmental standards?

A: Yes, this manometer carries both RoHS and CE certifications, guaranteeing adherence to international safety and environmental standards, making it suitable for industrial usage and global supply.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Dwyer USA Mark II Plastic Manometer Wholesaler Category

Mark II Model 41-2-AV Dwyer Manometer 0-2.5 inch W.C

Price 8500 INR / Piece

Minimum Order Quantity : 12 Pieces

Scale Range : 02.5 inch W.C

Accuracy : +3% FS %

Weight : 1.04 lb (472 g)/1.23 lb (558 g) Grams (g)

Usage : Air Filter Gage

Mark II MM-180 Dwyer Manometer 0-180 MM W.C

Price 8500 INR / Piece

Minimum Order Quantity : 12 Pieces

Scale Range : 0180 MM W.C

Accuracy : +3% FS %

Weight : 1.04 lb (472 g)/1.23 lb (558 g) Grams (g)

Mark II Model 40-250PA Dwyer Manometer Range 10-0-250 Pa

Price 8500 INR / Piece

Minimum Order Quantity : 12 Pieces

Scale Range : Range 100250 Pa

Accuracy : 3% FS. %

Weight : 1.23 lb (558 g). Grams (g)

Usage : Paint Booths

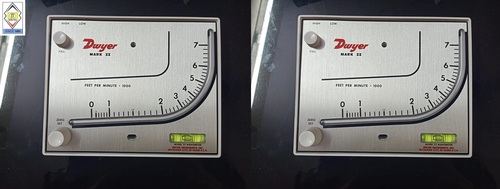

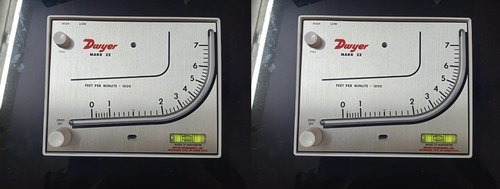

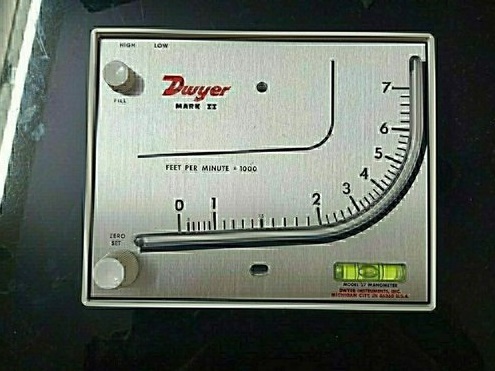

Mark II Model 27 Dwyer Manometer Range 0-7000 FPM

Price 8500 INR / Piece

Minimum Order Quantity : 12 Pieces

Scale Range : Range 07000 FPM

Accuracy : +3% FS %

Weight : 1.23 lb (558 g). Grams (g)

Usage : Air Velocity Measurement

Send Inquiry

Send Inquiry