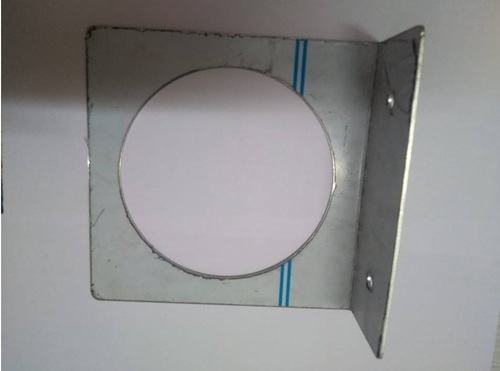

Magnehelic Gauge SS Plate Front Cover

Magnehelic Gauge SS Plate Front Cover Specification

- Bourdon Tube

- Not Applicable (Diaphragm Mechanism)

- Seal Material

- Neoprene Rubber Gasket

- Grade

- Industrial Grade

- Display

- Analog

- Sensor Type

- Diaphragm

- Thread

- 1/8 NPT

- Outer Size

- Approximately 100 mm Diameter

- Material

- Stainless Steel Front Plate, Aluminium Case

- Dial Material

- Aluminium with Printed Scale

- Pointer Material

- Aluminium, Black Anodized

- Processing Type

- CNC Machined

- Diameter

- 100 mm (Dial Diameter)

- Glass Size

- Standard Magnehelic Gauge Glass

- Mount Type

- Surface / Flush Mount

- Scale Range

- 0-60 Pa to 0-3000 mmWC (various available)

- Accuracy

- 2% of Full Scale

- Finishing

- Stainless Steel Polish

- Measure Pressure Of

- Low Differential Air/Gas Pressure

- Accessories

- Surface Mounting Bracket, Screws

Magnehelic Gauge SS Plate Front Cover Trade Information

- Minimum Order Quantity

- 12 Pieces

- Main Export Market(s)

- Eastern Europe, Western Europe, Africa, Central America, Middle East, South America, Asia, North America, Australia

- Main Domestic Market

- All India

About Magnehelic Gauge SS Plate Front Cover

Magnehelic Gauge SS Plate Front Cover

We are here to offer Magnehelic Gauge SS Plate Front Cover. It is designed to calibrate a broad spectrum of instruments from moving coil meters to process control systems and retain its precision over long periods in wide environmental conditions. These are customized as per as needs of clients.

Specifications:

- Metal of construction S.S. 304

- Dial size: 4"

- Ranges: mm/wc,In/wc, Pascal

- Enclosure type: consul type & wall mounting

- Front panel: zero calibration gas selector switch optional

Available in different specifications ranging from:

- 0-10,

- 0-25,

- 0-40,

- 0-50,

- 0-100 MM Wc , And

- 0- 60 pA,

- 0-250 pA.

Uses:

- Used for high accuracy-guaranteed within 2% of full scale and for the wide choice of 81 models available to suit your needs precisely.

Rugged Industrial Construction

Built with a high-quality stainless steel front plate and a die-cast aluminium back cover, the Magnehelic Gauge endures harsh industrial environments. The clear acrylic or polycarbonate window provides excellent visibility, while a neoprene rubber gasket ensures a dust- and splash-resistant seal.

Exceptional Accuracy and Versatility

This gauge offers precise analog readings with an accuracy of 2% of full scale, making it ideal for critical air and gas pressure monitoring. Available in various pressure ranges and featuring a diaphragm sensor mechanism, it suits a wide range of applications.

Easy Panel and Surface Mounting

Each unit is supplied with factory-provided mounting holes, a surface mounting bracket, and screws, enabling effortless integration into panels or onto surfaces. The polished stainless steel finish not only enhances durability but also provides an appealing, professional look.

FAQs of Magnehelic Gauge SS Plate Front Cover:

Q: How is the Magnehelic Gauge installed for panel or surface mounting?

A: The Magnehelic Gauge comes with factory-provided holes and is supplied with a mounting bracket and screws. This enables straightforward installation on panels or surfaces as per your application requirements.Q: What materials are used for the front and back covers of the gauge?

A: The front cover is crafted from high-grade stainless steel (SS-304 or SS-316), while the back cover is made from durable die-cast aluminium, ensuring strength and longevity even in demanding industrial settings.Q: When should I choose an SS-304 versus an SS-316 front plate?

A: SS-304 is suitable for general industry use, while SS-316 is preferred for environments requiring enhanced chemical resistance or exposure to corrosive substances.Q: Where can the Magnehelic Gauge be used?

A: This gauge is ideal for use in industrial settings such as HVAC systems, cleanrooms, laboratories, and air handling units, where accurate monitoring of low differential air or gas pressure is crucial.Q: What is the process for measuring pressure with this gauge?

A: The gauge utilizes a diaphragm mechanism to sense low pressure differentials. The analog pointer, mounted on an aluminium dial, displays the pressure value against printed scales for direct and accurate reading.Q: How does the ingress protection rating of IP54 benefit the user?

A: The IP54 rating ensures that the device is protected against limited dust ingress and splashes of water, making it reliable for use in environments where exposure to such elements is possible.Q: What are the benefits of the included neoprene rubber gasket?

A: The neoprene rubber gasket forms a tight seal between the front and back covers, preventing leaks and ingress of dust and moisture, prolonging the operational life of the gauge.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mounting Options Dwyer Instruments Category

Magnehelic Gauge L Plat

Price 450 INR

Minimum Order Quantity : 100 Pieces

Material : Other, Aluminum housing, plastic dial

Accessories : Two mounting brackets, screws, silicone tube

Processing Type : Other, Precision molded housing

Scale Range : 060 mm WC

Magnehelic Gauge Shape Plate

Price 450 INR

Minimum Order Quantity : 100 Pieces

Material : Other, Aluminum (Body), Polycarbonate (Window)

Accessories : Surface Mounting Screws Included

Processing Type : Other, DieCast Moulded

Scale Range : 0 60 Pa to 0 30,000 Pa (Varies by Model)

Industrial GI Magnehelic Gauge Box

Material : Other, Galvanized Iron (Box), ABS/Aluminium (Gauge body)

Accessories : Mounting Clamps, Screws

Processing Type : Other, DiePressed GI Sheet

Scale Range : 0500 Pa (or as per requirement)

Magnehelic Gauge SS BOX

Material : Other, Stainless Steel and Plastic

Accessories : SS BOX

Processing Type : Other, Mechanical

Scale Range : 0100 Pascals (example can vary)

Send Inquiry

Send Inquiry