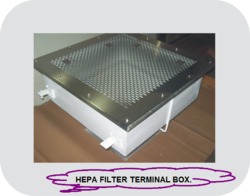

Hepa Filter Terminal Box

Price 12700 INR/ Piece

Hepa Filter Terminal Box Specification

- Media Type

- Glass fiber paper

- Flow Rate

- 600-1200 CFM

- Temperature Range

- 0C - 60C

- Filtration Grade

- HEPA (H13/H14)

- Capacity

- Depends on selected model

- Filter Type

- HEPA filter terminal box

- Pressure

- Initial resistance: 250 Pa

- Connecting Type

- Flanged / Duct connection

- Efficiency (%)

- 99.97% @ 0.3 microns

- Cleaning Method

- Replacement

- Condition

- New

- Material

- Galvanized steel / Aluminum

- Mesh

- Fine mesh pre-filter integrated

- Diameter

- Standard sizes: 610 mm x 610 mm / 1220 mm x 610 mm

- Construction

- Rugged box type with sealed corners

- Medium Filter

- Glass fibre media

- Weight

- Approx. 10-15 kg (depends on size)

- Shape

- Rectangular box

- Feature

- HEPA filtration, Ceiling/terminal mounted, air-tight design, easy installation and maintenance

Hepa Filter Terminal Box Trade Information

- Minimum Order Quantity

- 12 Pieces

- Supply Ability

- 100 Pieces Per Week

- Delivery Time

- 10 Days

About Hepa Filter Terminal Box

We are manufacturer and supplier of high quality HEPA Filter Terminal Box, and Industrial HEPA Filter Terminal Box from Ghaziabad, India. We are manufacturing and supplying HEPA Filter Terminal Box, and Industrial HEPA Filter Terminal Box to various cities like, NEW DELHI, NOIDA, GHAZIABAD, MEERUT, SONIPAT, MANESAR, GREATER NOIDA, KANPUR, AMBALA, LUDHIANA, PAONTA SAHIB, MUZAFFARNAGAR, RANCHI,PATNA, JAIPUR, JAMMU, INDOR, GUJARAT, AHMEDABAD, MUMBAI, PUNE and many more.

We have uniquely positioned ourselves as a dependable firm, engaged in manufacturing, trading, exporting and supplying a commendable array of HEPA Filter Terminal Box. The offered terminal box is used as boxes for flange type HEPA filter. This product is manufactured using excellent quality raw material and latest technology by our skilled professionals. In order to ensure quality, this is stringently tested on various parameters by our experts. Apart from this, clients can avail the offered terminal box from us at market leading prices.

Technical specification

| Minimum order quantity | 12 number |

| Filter medium material | Microfiber |

| 5 micron | 10 micron |

| 20 micron | Gi frame |

| Aluminum frame | Ss frame |

High-Efficiency Filtration in Demanding Environments

This HEPA filter terminal box provides essential air purification in environments requiring stringent cleanliness, such as pharmaceutical plants, laboratories, hospitals, and cleanrooms. The glass fibre media ensures H13/H14 filtration grade, capturing even the tiniest airborne particles with 99.97% efficiency at 0.3 microns, supporting superior contamination control.

Durable Construction with Seamless Integration

Manufactured from sturdy galvanized steel or aluminum, the terminal boxs rugged, sealed-corner design is optimized for air-tight performance and longevity. Its powder-coated or anodized finish resists corrosion, ensuring consistent functionality in highly controlled settings. The units compatibility with ceiling mounting or duct/flanged connections makes it highly adaptable.

Easy Installation and Maintenance

Installation is straightforward, whether integrated into a ceiling grid or connected as a terminal air supply. The filter unit features intuitive access for filter replacement, significantly reducing maintenance downtime. The built-in fine mesh pre-filter prolongs the primary HEPA filters life, ensuring sustained high performance.

FAQs of Hepa Filter Terminal Box:

Q: How is the HEPA filter terminal box typically installed in a cleanroom or laboratory?

A: This terminal box is designed for ceiling mounting or as a terminal air supply via flanged or duct connection. Installation is straightforward, enabling quick integration into existing systems in cleanrooms, hospitals, laboratories, and similar critical environments.Q: What is the main benefit of using a HEPA filter terminal box in pharmaceutical or hospital settings?

A: These terminal boxes deliver exceptional air purification by trapping 99.97% of particles at 0.3 microns, significantly reducing the risk of airborne contamination and supporting strict hygiene and quality standards essential in healthcare and pharmaceutical manufacturing.Q: When should the filter media within the terminal box be replaced?

A: HEPA filter media should be replaced when the initial resistance approaches 250 Pa or as indicated by routine airflow and differential pressure checks, ensuring consistent air quality and optimal filter performance.Q: What materials are used in the construction of the terminal box, and why?

A: The terminal box is constructed from galvanized steel or aluminum for durability and corrosion resistance. The use of these materials, in combination with powder-coated or anodized finishes, ensures a long service life and stable operation in high-humidity or sterile settings.Q: Where are these HEPA filter terminal boxes most commonly utilized?

A: They are most widely used in cleanrooms, hospitals, pharmaceutical plants, diagnostic labs, and research facilitiesenvironments where particulate control and sterile conditions are paramount.Q: How does the design ensure air-tight operation and minimal leakage?

A: The combination of a rugged box-type structure, sealed corners, polyurethane or hot melt sealant, and neoprene/PU foam gaskets delivers an exceptionally air-tight and leak-proof solution, with air leakage rates maintained below 0.5% at rated flow.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in AHU Filter Manufacture From India Category

AHU Pre Filter In Nalagarh Himachal Pradesh

Price 1500 INR / Piece

Minimum Order Quantity : 12 Pieces

Size : Customized

Color : WHITE

Shape : Square

Filtration Grade : Pre Filter

AHU PRE FILTER IN Namkom Industrial Area Ranchi Jharkhand

Price 1500 INR / Piece

Minimum Order Quantity : 12 Pieces

Size : Customized

Color : WHITE

Shape : Square

Filtration Grade : Pre Filter

AHU PRE FILTER In Rengali Sambalpur Odisha

Price 1500 INR / Piece

Minimum Order Quantity : 12 Pieces

Size : Customized

Color : WHITE

Shape : Square

Filtration Grade : Pre Filter

AHU Pre Filter In Kalyan Maharashtra

Price 1500 INR / Piece

Minimum Order Quantity : 12 Pieces

Size : Customized

Color : WHITE

Shape : Square

Filtration Grade : Pre Filter

Send Inquiry

Send Inquiry