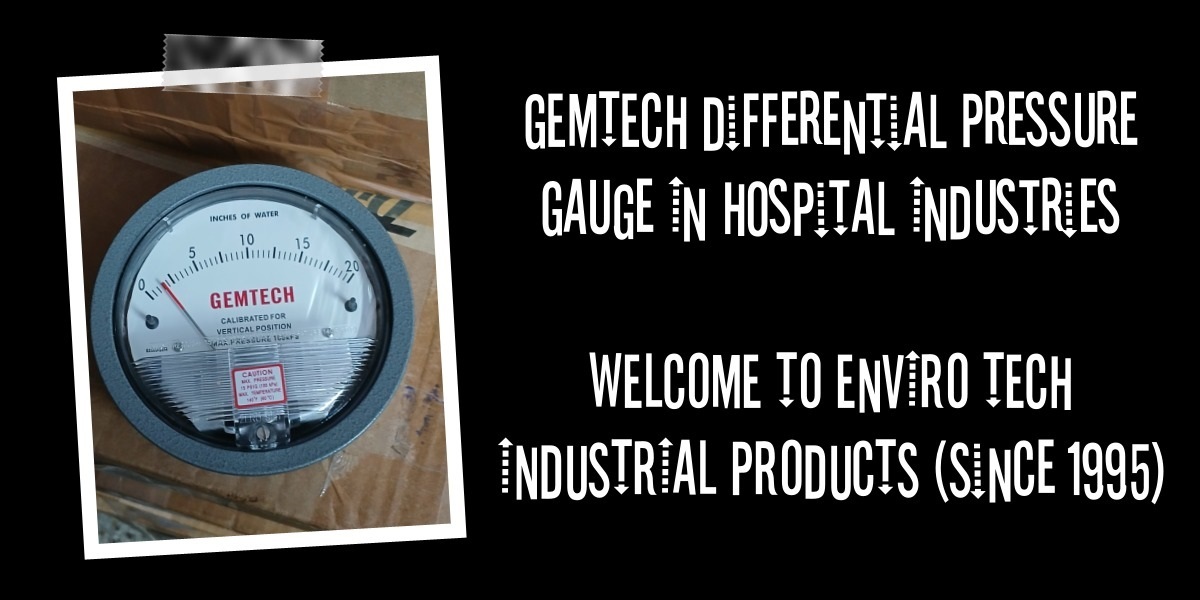

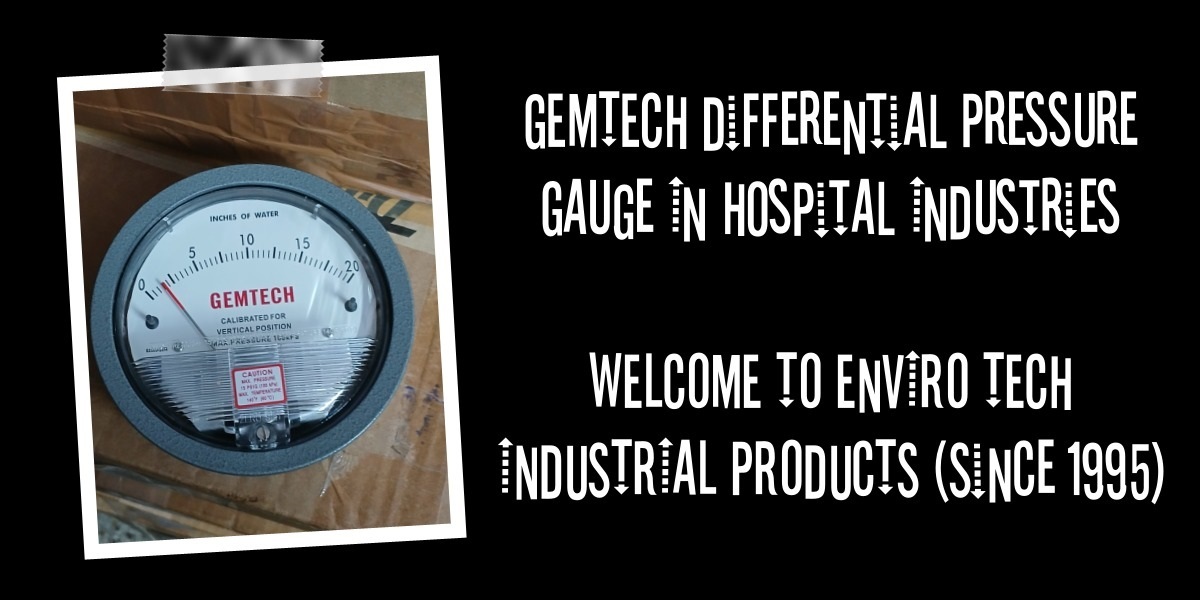

GEMTECH Differential Pressure Gauge Wholesaler Near EHIRCL

Price 4500 INR/ Piece

GEMTECH Differential Pressure Gauge Wholesaler Near EHIRCL Specification

- Sensor Type

- Differential Pressure Sensor

- Display

- Analog

- Bourdon Tube

- Stainless Steel

- Thread

- 1/4 BSP

- Outer Size

- 110 mm

- Grade

- Industrial Grade

- Seal Material

- Neoprene

- Material

- Aluminum Die Cast

- Dial Material

- Aluminum

- Pointer Material

- Aluminum

- Processing Type

- Forged

- Diameter

- 100 mm

- Glass Size

- 100 mm

- Mount Type

- Surface Mount

- Scale Range

- 0-6000 Pa

- Accuracy

- 2% F.S.

- Finishing

- Powder Coated

- Measure Pressure Of

- Air and Non-corrosive Gases

- Accessories

- Mounting Bracket, Installation Manual

About GEMTECH Differential Pressure Gauge Wholesaler Near EHIRCL

GEMTECH Differential Pressure Gauge Wholesaler Near EHIRCL

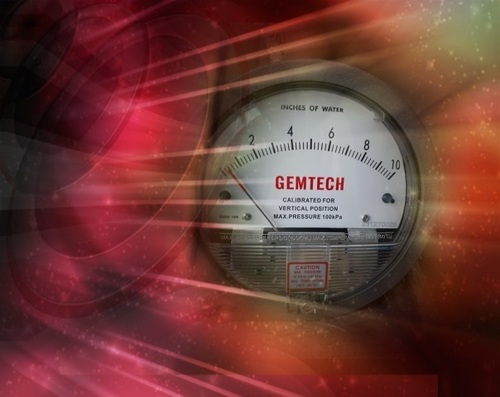

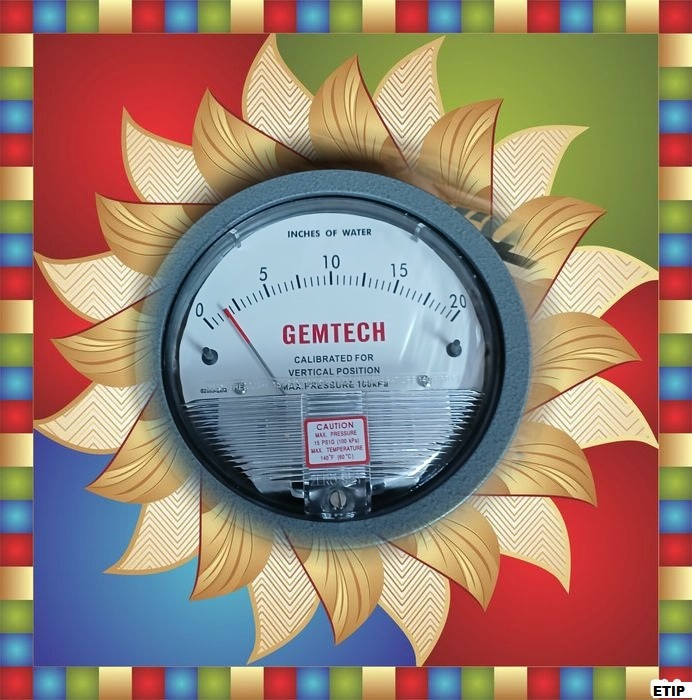

Series G2000 GEMTECH Differential Pressure Gauges are Widely Utilized For Measuring Pressure of Fan And Blowing Machine, resistance of Filter, Wind Speed, Furnace Pressure, Differential Pressure Of Pore Plate,The Pressure of drum water level, Liquid Amplifier And Hydraulic Pressure System. Meantime,They Are Used To Control The Automatic Valve And Specific Value Of Air-Producer Gas In Combustion And They Are Used To Test Blood Pressure And Respiratory Pressure In Medical Health Care Equipment. There Are More Than 81 Models To Suit Your Needs Precisely.The Key Components Adopt Import Materi

SPECIFICATION

FEATURES

PRODUCT APPLICATIONS

MODELS & ORDERING

GEMTECH By Model Number Popularity

- FILTER BY

- Range - MM Of Water

| Model | Description |

|---|---|

| G2000-100MM | DPG,Range 0-100 MM W.C., Minor Divisions 2.0. |

| G2000-10MM | DPG,Range 0-10 MM W.C.,Minor Divisions .20,Calibrated For Vertical Scale Position. |

| G2000-150MM | DPG,Range 0-150 MM W.C. |

| G2000-15MM | DPG,Range 0-15 MM W.C. |

| G2000-200MM | DPG,Range 0-200 MM W.C. |

| G2000-250MM | DPG,Range 0-250 MM W.C. |

| G2000-25MM | DPG,Range 0-25 MM W.C. Minor Divisions .50. |

| G2000-300MM | DPG,Range 0-300 MM W.C. |

| G2000-50MM | DPG,Range 0-50 MM W.C., Minor Divisions 1.0. |

| G2000-6MM | DPG,Range 0-6 MM W.C., Minor Divisions .20, Calibrated For Vertical Scale Position. |

| G2000-80MM | DPG,Range 0-80 MM W.C., Minor Divisions 2.0. |

Additional Information:

- Item Code: GEMTECH-Differential-Pressure-Gauges-Dealers-Near-EHIRCL

- www.envirotechdelhi.in

- www.envirotechdelhi.net

- www.envirotechindia.info

Precise Differential Pressure Measurement

Designed for demanding air and non-corrosive gas applications, GEMTECHs gauge delivers reliable measurement accuracy of 2% F.S., ensuring effective control in clean rooms and HVAC installations. Its durable construction and industrial-grade components guarantee long-term stability even in rigorous environments.

Versatile Installation Options

Choose between back or bottom connection positions based on system requirements. The gauges forged aluminum die-cast body and powder-coated finish provide resilience against harsh operating conditions, while the supplied mounting bracket and installation manual ensure quick and secure installation for professional and industrial settings.

User-Friendly Operation and Maintenance

Factory calibration and analog display enable immediate, intuitive readings. The surface mount type, 1/4 BSP thread, and easily accessible window (acrylic/polycarbonate) facilitate routine inspection and maintenance, streamlining process control for those managing air filters, clean rooms, and HVAC systems.

FAQs of GEMTECH Differential Pressure Gauge Wholesaler Near EHIRCL:

Q: How do I install the GEMTECH Differential Pressure Gauge in my HVAC system or clean room?

A: Installation is straightforward with the surface mount design. Use the supplied mounting bracket and follow the installation manual. Choose the connection positionback or bottomas per your systems requirements and connect using the 1/4 BSP thread. Ensure all seals are secured for accurate readings.Q: What processes benefit from using this differential pressure gauge?

A: This gauge is ideal for applications requiring continuous monitoring of air and non-corrosive gas pressures, notably in HVAC systems, clean rooms, air filtration units, and controlled environments where precision is vital for maintaining safety and compliance.Q: When should I recalibrate the GEMTECH Differential Pressure Gauge?

A: The gauge is factory calibrated for immediate use. For optimal performance, periodic recalibration may be necessary based on your applications regulatory standards or if measurement accuracy is in question due to prolonged use. Refer to industry guidelines for recalibration intervals.Q: Where can I source the GEMTECH Differential Pressure Gauge as a wholesaler near EHIRCL, India?

A: You can purchase the GEMTECH Differential Pressure Gauge through recognized manufacturers, suppliers, traders, and wholesalers located near EHIRCL, India. Contact authorized GEMTECH distributors for bulk pricing, technical support, or specific order requirements.Q: What are the benefits of using the GEMTECH Differential Pressure Gauge in industrial settings?

A: With industrial-grade accuracy (2% F.S.), robust construction, and IP 55 case protection, this gauge ensures reliable and safe operation in demanding environments. Its versatility, easy installation, and clear analog display support ongoing process efficiency and regulatory compliance.Q: What medium can be measured with this differential pressure gauge?

A: The product is designed for measuring pressures of air and non-corrosive gases, making it suitable for clean room, filtration, and ventilation systems where chemical compatibility and accurate monitoring are essential.Q: How does the IP 55 protection and powder coated finish benefit operational reliability?

A: IP 55 case protection shields the gauge from dust and low-pressure water jets, while the powder coated finish resists corrosion and wear, ensuring the device remains accurate and functional in industrial environments over extended periods.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in GEMTECH Differential Pressure Gauge Wholesaler In Hospital Industries Category

GEMTECH Differential Pressure Gauge Wholesaler Near Safdarjung Hospital

Price 4500 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : GEMTECH Differential Pressure Gauge Wholesaler Near Safdarjung Hospital

Accuracy : 2% (HA model 1) of FS (3% (HA 1.5%) on 0, 100PA, 125PA, 10MM and 4% (HA 2%) on 00, 60PA, 6MM Ranges), Throughout Range at 70F (21.1C).

Scale Range : MM WC/ CM / PAC / KPA / INCH

Usage : POWER PLANT,CEMENT PLANT,STEEL PLANT,FERTILIZER,TEXTILE

GEMTECH Differential Pressure Gauge Wholesaler Near Ram Manohar Lohia Hospital

Price 4500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : GEMTECH Differential Pressure Gauge Wholesaler Near Ram Manohar Lohia Hospital

Accuracy : 2% (HA model 1) of FS (3% (HA 1.5%) on 0, 100PA, 125PA, 10MM and 4% (HA 2%) on 00, 60PA, 6MM Ranges), Throughout Range at 70F (21.1C).

Scale Range : MM WC/ CM / PAC / KPA / INCH

Usage : POWER PLANT,CEMENT PLANT,STEEL PLANT,FERTILIZER,TEXTILE

GEMTECH Differential Pressure Gauge Wholesaler Near Deen Dayal Upadhyay Hospital

Price 4500 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : GEMTECH Differential Pressure Gauge Wholesaler Near Deen Dayal Upadhyay Hospital

Accuracy : 2% (HA model 1) of FS (3% (HA 1.5%) on 0, 100PA, 125PA, 10MM and 4% (HA 2%) on 00, 60PA, 6MM Ranges), Throughout Range at 70F (21.1C).

Scale Range : MM WC/ CM / PAC / KPA / INCH

Usage : Pharmaceutical Industries

GEMTECH Differential Pressure Gauge Wholesaler Near Mata Chanan Devi Hospital

Price 4500 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : GEMTECH Differential Pressure Gauge Wholesaler Near Mata Chanan Devi Hospital

Accuracy : 2% (HA model 1) of FS (3% (HA 1.5%) on 0, 100PA, 125PA, 10MM and 4% (HA 2%) on 00, 60PA, 6MM Ranges), Throughout Range at 70F (21.1C).

Scale Range : MM WC/ CM / PAC / KPA / INCH

Usage : POWER PLANT,CEMENT PLANT,STEEL PLANT,FERTILIZER,TEXTILE

Send Inquiry

Send Inquiry