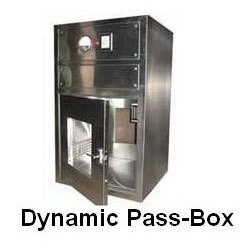

Dynamic Pass Box

Price 90000 INR/ Piece

Dynamic Pass Box Specification

- Output

- Filtered Air, ISO Class 5 standard

- Hole Size

- Custom as per requirement

- Features

- Interlocking Doors, Indicator Lights, UV Lamp, SS Handles, View Glass, Door Sensors

- Energy Consumption

- Low; Energy Efficient Design

- Frequency

- 50 Hz

- Control System

- Microprocessor Based

- Color

- Powder Coated/SS Finish

- Application

- Pharmaceutical, Hospitals, Laboratories, Cleanrooms

- Humidity %

- Up to 85% RH

- Filters

- Pre-filter (10), HEPA filter (0.3)

- Efficiency (%)

- >99.99% @ 0.3 micron

- Dust

- HEPA/ULPA Filtration

- Dust %

- Minimum, meets ISO standards

- Maintenance Type

- Easy Access for Service

- Filtration Property

- HEPA/ULPA filtration

- Material

- Stainless Steel (SS 304/316)

- Flow Rate

- 450-600 m3/hr

- Pressure Range

- Positive Pressure (0.5 1.0 mm WG)

- Noise Level

- < 65 dB

- Ventilation

- Built-in Fan Module

- Connectivity Type

- Standalone

- Installation Type

- Wall Mounted/Floor Mounted

- Automatic Grade

- Semi-Automatic

- Capacity

- Customized Sizes Available

- Power

- 100 Watts

- Voltage

- 230V AC, 50Hz

- Dimension (L*W*H)

- 600 x 600 x 600 mm (standard), other sizes on request

- Weight

- Approx. 55 Kg

Dynamic Pass Box Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Payment Terms

- Cash on Delivery (COD), Paypal, Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Main Export Market(s)

- Western Europe, Australia, Eastern Europe, Middle East, Central America, South America, Asia, North America, Africa

- Main Domestic Market

- Chandigarh, Himachal Pradesh, Pondicherry, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, Lakshadweep, South India, East India, West India, Andaman and Nicobar Islands, Assam, Arunachal Pradesh, Bihar, Goa, Jammu and Kashmir, Jharkhand, Karnataka, Madhya Pradesh, Mizoram, Meghalaya, Manipur, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, Nagaland, Delhi, Kerala, Maharashtra, Haryana, Gujarat, North India, Andhra Pradesh, Central India, Odisha, Chhattisgarh, Uttar Pradesh, All India

About Dynamic Pass Box

Dynamic Pass Box

Technical Specifications:

- Material of construction: - S.S.304 / 316 PVC coated matt finish OR CRCA Powder Coated with RAL 9004 Color Shade.

Suction Filter:

- Filter Casing S.S304 / 316 Flange Type.

- Efficiency 95% down to 5 micron { EU 4 rating.}

- Madia Non Woven Synthetic Media sandwiched between two layers of High Density Polyethylene Mesh.

Supply Filter:

- Filter Casing Aluminum Factory extruded section.

- Efficiency 99.999% down to 0.001 micron { EU 14 rating.}

- Madia Micro fiberglass paper media {Imported } Pleated along with hot Melt Glue.

Blower motor assembly:

- Enviro tech Make, 230Volts, 50Hz, Single- Phase imported Blower along with inbuitt motor

Accessories:

- Hour Meter Connected to UB Light.

Door Handles:

- Magnehelic/Minihelic Pressure Gauge.

Electrical details:

- 8/20w, Fluorescent light with milky diffuser.

- 8/15w, UV light along with Hour Meter.

- 12 Volt, Electromagnet for door interlocking.

- 12 Volt, Buzzer.

- 12 Volt Indicator lamps.

- 16 Amps. Three pin top along with connection cable

Selection Chart:

| Model No. | Overall Dimension {MM} | Workspace Dimensions {MM} | Electrica | ||||

| | W | D | H | W | D | H | SUPPLY { PHASE } |

| ETIP / 2-2-2 | 750 | 710 | 1250 | 610 | 610 | 610 | SINGLE |

| ETIP / 3-3-3 | 1055 | 1015 | 1555 | 915 | 915 | 915 | SINGLE |

| NOTE ALL OTHER DIMENSIONS ARE AVAILABLE AS PER REQUIREMENTS | |||||||

Advanced Door Interlocking for Safety

The Dynamic Pass Box is engineered with an intelligent electromagnetic interlock system to prevent simultaneous door opening. Visual and audio alarms alert users during door operation, safeguarding the cleanroom from contamination. Door status indicators and sensors provide real-time monitoring, enhancing operational safety and efficiency during material transfer processes.

Efficient Sterilization and Air Filtration

Equipped with a 15-watt optional UV lamp and integrated HEPA/ULPA filtration, the pass box ensures effective sterilization and contaminant-free airflow. Its advanced microprocessor-based control system maintains air velocity and pressure, creating a positive pressure environment to minimize dust ingress and comply with stringent cleanroom standards.

Customizable for Diverse Applications

Available in various sizes, finishes, and mounting options, the Dynamic Pass Box suits a wide range of pharmaceutical, medical, and laboratory settings. Optional accessories like data logging units and remote monitoring enhance traceability, while easy-to-remove panels support swift maintenance. Its energy-efficient design and compliance with cGMP, ISO, and CE standards make it a preferred choice for modern cleanrooms.

FAQs of Dynamic Pass Box:

Q: How does the door interlocking system work in the Dynamic Pass Box?

A: The electromagnetic door interlocking system ensures that only one door can be opened at a time, preventing cross-contamination during material transfer. Visual and audio alarms activate when a door is opened, and LED indicators show the current status of each door, providing added security for cleanroom operations.Q: What are the benefits of the UV lamp feature?

A: The optional 15-watt UV lamp offers enhanced sterilization within the pass box chamber, effectively reducing microbial contamination. This feature supports strict hygiene protocols in pharmaceutical, healthcare, and laboratory environments, ensuring a safer transfer process for sensitive materials.Q: When should the removable service access panels be used?

A: Rear and side removable panels allow easy access for routine maintenance or servicing. Use these panels during scheduled filter replacements, cleaning, or troubleshooting, ensuring minimal downtime and efficient upkeep of hygiene standards within the cleanroom.Q: Where is the Dynamic Pass Box typically installed?

A: This pass box is designed for wall or floor mounting in cleanrooms, laboratories, pharmaceutical facilities, and hospitals. Its versatile installation capability allows for integration into various clean zones, supporting controlled material transfer between different classes of environments.Q: What is the recommended process for transferring materials using the pass box?

A: Place material inside the pass box, close the door, and allow the interlock system to activate. Wait for the indicator light to signal safe transfer and the audio/visual alarm to remain silent. After the cycle completes, open the second door to retrieve the material without compromising cleanroom integrity.Q: How does the filtration system maintain air quality standards?

A: The built-in HEPA/ULPA filtration system achieves greater than 99.99% efficiency at 0.3 microns, maintaining ISO Class 5 air cleanliness. Pre-filters capture larger particles, while the main HEPA filter ensures purified air output, reducing dust and microbial load according to ISO standards.Q: What makes the Dynamic Pass Box energy efficient and durable?

A: Its construction from high-quality stainless steel (SS 304/316), advanced microprocessor controls, and low-power consumption design (100 watts, 230V AC) result in robust corrosion resistance and minimal energy usage. The equipments surface finish options and reliable electronics add to its longevity and reduced operational costs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Clean Room Equipment Category

Portable Desk Laminar Air Flow

Installation Type : Portable

Efficiency (%) : High efficiency

Application : Laboratory and industrial cleanroom environments

Features : Portable ergonomic design digital controls

Automatic Grade : Automatic

Material : Metal and glass

Interlocking Pass Box

Installation Type : Other, Wall Mounted

Efficiency (%) : High

Application : Industrial

Features : Interlocking mechanism robust design

Automatic Grade : Automatic

Material : Stainless Steel

Ceiling Suspended Laminar Flow

Installation Type : Portable

Efficiency (%) : 99.5

Application : Industrial

Features : Durable

Automatic Grade : Automatic

Material : Mild Steel

Pass Box

Installation Type : Portable

Efficiency (%) : 99.5

Application : Industrial

Features : Durable

Automatic Grade : Automatic

Material : Mild Steel

Send Inquiry

Send Inquiry