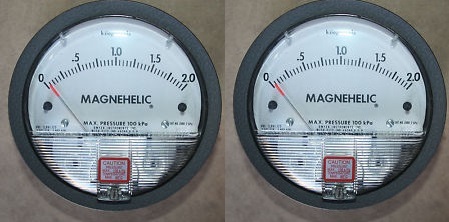

Dwyer USA Model 2304 Magnehelic Gage Range 2-0-2 Inch WC

Dwyer USA Model 2304 Magnehelic Gage Range 2-0-2 Inch WC Specification

- Grade

- Industrial

- Sensor Type

- Diaphragm

- Display

- Analog

- Outer Size

- Approximately 4 diameter (101.6 mm)

- Thread

- 1/8 NPT

- Seal Material

- Silicone or Buna-N gasket

- Material

- Die-cast aluminum case with clear acrylic cover

- Dial Material

- Acrylic

- Pointer Material

- Red tipped aluminum

- Processing Type

- Precision engineered

- Diameter

- 4 inches

- Glass Size

- Clear acrylic

- Mount Type

- Surface / Flush Mount

- Scale Range

- 2-0-2 Inch WC (Water Column)

- Accuracy

- 2% of full scale

- Finishing

- Powder coated/Aluminum brushed finish

- Measure Pressure Of

- Low air and non-corrosive gases

- Accessories

- Two 1/8 NPT plugs, two 1/8 NPT to rubber tubing adapters, three mounting adapters, and screws

Dwyer USA Model 2304 Magnehelic Gage Range 2-0-2 Inch WC Trade Information

- Minimum Order Quantity

- 12 Pieces

- Payment Terms

- Cash on Delivery (COD), Paypal, Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Main Export Market(s)

- Australia, Central America, North America, Eastern Europe, Western Europe, Middle East, Africa, Asia

- Main Domestic Market

- All India

About Dwyer USA Model 2304 Magnehelic Gage Range 2-0-2 Inch WC

Dwyer 2304 Differential Pressure Gage, Range 2-0-2 Inch WCÂ (inches of water), minor divisions .10, calibrated for vertical scale position

Using Dwyer's simple, frictionless Magnehelic gage movement, it quickly indicates low air or non-corrosive gas pressures--either positive, negative (vacuum) or differential. The design resists shock, vibration and over-pressures. No manometer fluid to evaporate, freeze or cause toxic or leveling problems. It's inexpensive, too.

The Magnehelic gage is the industry standard to measure fan and blower pressures, filter resistance, air velocity, furnace draft, pressure drop across orifice plates, liquid levels with bubbler systems and pressures in fluid amplifier or fluidic systems. It also checks gas-air ratio controls and automatic valves, and monitors blood and respiratory pressures in medical care equipment.

Note: May be used with Hydrogen. Order a Buna-N diaphragm. Pressures must be less than 35 psi.

What's included with the Dwyer 2304

Dwyer 2304 Magnehelic Differential Pressure Gauge (2-0-2 Inch w.c.), Vertical ScaleÂ

Ask a Question About Dwyer 2304 Magnehelic Differential Pressure Gauge (2-0-2 Inch w.c.), Vertical Scal

Exceptional Pressure Measurement Accuracy

Manufactured for industrial use, the Model 2304 Magnehelic Gage offers 2% full-scale accuracy, ensuring reliable readings for HVAC, filter monitoring, and clean room applications. Its diaphragm sensor and precision-engineered components guarantee dependable performance.

Robust & User-Friendly Design

Housed in a die-cast aluminum case with a clear acrylic cover, this gage withstands challenging environments. The powder-coated/aluminum brushed finish enhances durability, and external zero adjustment provides convenient calibration without disassembly.

Hassle-Free Installation and Versatile Mounting

The gage is designed for swift installationmount vertically using provided hardware for either surface or flush mounting. Accessories such as NPT plugs and tubing adapters ensure compatibility with a variety of setups, making it suitable for diverse industrial environments.

FAQs of Dwyer USA Model 2304 Magnehelic Gage Range 2-0-2 Inch WC:

Q: How do I install the Dwyer Model 2304 Magnehelic Gage?

A: The gage is designed for vertical mounting as standard. Use the included mounting adapters and screws to secure it to a surface or flush panel. Simply connect appropriate 1/8 NPT fittings or use supplied adapters for rubber tubing, ensuring all connections are secure before operation.Q: What types of applications is the Model 2304 suitable for?

A: This instrument is ideal for monitoring low-pressure air and non-corrosive gases in HVAC systems, filter monitoring, duct static pressure, clean rooms, and fan/blower pressure applications due to its precise and immediate mechanical response.Q: When should the Magnehelic Gage be zero-adjusted?

A: It is recommended to check and, if necessary, adjust the zero setting periodically or anytime the gage is relocated or recalibrated. Use the external adjustment screw for easy zeroing without disassembling the unit.Q: Where can the gage be used in terms of temperature and environment?

A: The Model 2304 is suitable for environments with temperatures between -7C to 60C (20F to 140F). It is built for industrial settings with a robust die-cast aluminum body and is not intended for corrosive gas measurement.Q: What is the process for reading and maintaining the Magnehelic Gage?

A: Read the analog display by observing the red-tipped aluminum pointer against the acrylic dial. For maintenance, periodically check hose fittings, zero calibration, and keep the clear acrylic cover free from dust and debris for optimal visibility.Q: Why should I use this gage for my HVAC or clean room application?

A: The Model 2304 provides rapid, accurate, and reliable pressure indication, which is crucial for ensuring environmental controls in HVAC or clean room operations. Its sturdy construction and ease of installation offer long-term performance with minimal maintenance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sensocon - Dwyer S2000 Differential Pressure Gauge Category

Dwyer 2005D Magnehelic Differential Pressure Gauge

Minimum Order Quantity : 12 Pieces

Material : Other, Diecast Aluminum Case, Acrylic Lens, BunaN Diaphragm

Thread : 1/8 NPT Female

Diameter : 115 mm (4.5 inch nominal dial)

Accessories : 2 Pressure Taps, Mounting Screws, Instruction Sheet

Dwyer USA Model 2250 Magnehelic Gage Range 0-250 Inch WC

Minimum Order Quantity : 12 Pieces

Material : Other, Diecast aluminum case, acrylic lens

Thread : 1/8 NPT (back and bottom connections)

Diameter : 41/2 inch (115 mm)

Accessories : Two 1/8 NPT plugs, mounting hardware, and standard instructions

Dwyer 2000-250PA Magnehelic Differential Pressure Gauge

Price 3500 INR

Minimum Order Quantity : 12 Pieces

Material : Other, Diecast Aluminum housing, Acrylic cover, BunaN diaphragm

Thread : 1/8 NPT female (high and low pressure ports)

Diameter : 4.5 inches (115 mm)

Accessories : Two 1/8 NPT plugs for duplicate high and low pressure taps, two 1/8 pipe thread to rubber tubing adapters, mounting bracket, and necessary screws

Dwyer Magnehelic Differential Pressure Gauge Model 2000-2KPA

Minimum Order Quantity : 12 Pieces

Material : Other, Diecast aluminum case, acrylic cover

Thread : 1/8 Female NPT

Diameter : 4 inches (101.6 mm)

Accessories : Two 1/8 NPT plugs, two mounting screws, and instruction sheet included

Send Inquiry

Send Inquiry