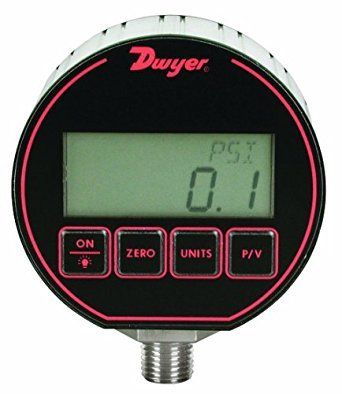

DWYER USA DPG-206 Digital Pressure Gauge

DWYER USA DPG-206 Digital Pressure Gauge Specification

- Sensor Type

- Piezoresistive

- Bourdon Tube

- Not Applicable (Digital)

- Display

- 4-digit Backlit LCD

- Seal Material

- Buna-N

- Thread

- 1/4 NPT Male

- Outer Size

- Approx. 104 x 55 mm

- Grade

- Industrial

- Material

- ABS Plastic Housing, Stainless Steel Wetted Parts

- Dial Material

- Not Applicable (Digital)

- Pointer Material

- Not Applicable (Digital)

- Processing Type

- Digital Microprocessor Based

- Diameter

- Approx. 55 mm (Display Diameter)

- Mount Type

- Bottom Connection

- Scale Range

- -5 to 5 psi (5.000 psi)

- Accuracy

- 0.25% FS

- Finishing

- Matte with Protective Coating

- Measure Pressure Of

- Air, Non-corrosive Gases and Liquids

- Accessories

- Protective Rubber Boot, User Manual, Batteries

DWYER USA DPG-206 Digital Pressure Gauge Trade Information

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque

- Main Export Market(s)

- Australia, Middle East, Western Europe, Africa, Central America, South America, Asia, Eastern Europe, North America

- Main Domestic Market

- All India

About DWYER USA DPG-206 Digital Pressure Gauge

Series DPG-200 Digital Pressure Gage, 200 psig

3-in-1: Gage, Transmitter & Switch

The Series DPG-200 Digital Pressure Gage has a precise ±0.25% full scale accuracy. The 4 digit digital display will reduce the potential for errors in readings by eliminating parallax error commonly produced with analog gages. The DPG-200 is packaged in a durable extruded aluminum case designed to meet NEMA 4X (IP66). The unit is powered by 12-24 VDC/VAC and contains two alarm set points along with a 4-20 mA process output. A four-button keypad allows easy access to features. These features include backlight, peak and valley, auto zero and conversion of the pressure units.

DPG-206

Digital pressure gage, selectable engineering units: 200.0 psig, 14.06 kg/cm², 13.79 bar, 407.2" Hg, 461.4 ft w.c., 449.7 ft seawater @ 4°C, 1379 kPa, 3200 oz/in², 5536" w.c.

- Level Control

- Pump Control

- Process Control

- Compressor Control

Reliable Precision for Industrial Applications

With its high resolution of 0.001 psi up to 19.999 psi and accuracy of 0.25% of full scale, the DPG-206 is tailored for applications demanding reliable, repeatable pressure measurements. Its rapid sampling and display update rate ensure operators receive near-instantaneous feedback, supporting efficient process monitoring on factory floors.

Rugged Design with User-Friendly Features

Built to withstand tough working conditions, the DWYER DPG-206 is IP67-rated for waterproofing, features a stainless steel process connection, and comes with a protective rubber boot. The intuitive interface, handy zero function, and backlit LCD display make operations straightforward in any lighting condition, while its sturdy ABS plastic case safeguards your investment.

Power, Portability, and Easy Integration

Powered by two readily available AAA batteries, this pressure gauge offers excellent portability and can be used across sites without complicated installation. Its 1/4 NPT male connection and compact size (104 x 55 mm) ensure compatibility with standard setups, streamlining integration into existing systems in industrial environments.

FAQs of DWYER USA DPG-206 Digital Pressure Gauge:

Q: How does the DWYER DPG-206 measure pressure in industrial environments?

A: The DPG-206 uses a piezoresistive sensor to digitally measure the pressure of air, non-corrosive gases, and compatible liquids. Its 4-digit LCD display provides readings with high resolution and accuracy, making it suitable for sensitive industrial monitoring.Q: What are the benefits of the IP67 waterproof rating for this pressure gauge?

A: The IP67 rating ensures that the gauge is dust-tight and can withstand immersion in water up to 1 meter, making it highly resistant to challenging environments and accidental spills, thus prolonging the life and performance of the device.Q: When should I use the on-key zero function?

A: Use the on-key zero function whenever you need to reset the gauge to zero before taking a measurement. This feature helps eliminate any residual pressure errors, ensuring accuracy for each new reading.Q: Where can the DPG-206 be installed, and what media can it measure?

A: This gauge can be installed in any industrial setting using the bottom-mounted 1/4 NPT male thread. It is designed to measure the pressure of air, as well as non-corrosive gases and liquids that are compatible with its stainless steel wetted parts and Buna-N seal.Q: What is the process for replacing the batteries and maintaining the device?

A: To replace the batteries, simply open the battery compartment, insert two new AAA batteries, and close it securely. For maintenance, keep the device clean, periodically check the protective rubber boot and seals, and store it dry when not in use.Q: How does the display and response rate benefit the user during operation?

A: The backlit 4-digit LCD updates five times per second, and the device has a response time under 100 milliseconds. Together, these features provide quick, easy-to-read pressure data, facilitating fast decision-making and process control in dynamic industrial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Dwyer USA DPG 200 Digital Pressure Gage Wholesaler Category

DWYER USA DPG-207 Digital Pressure Gauge

Thread : 1/4 NPT (Male)

Seal Material : Viton ORing

Outer Size : Approx. 100 mm Diameter Housing

Mount Type : Other, Bottom Connection, Direct Mount

Grade : Industrial

Glass Size : Not Applicable (Digital Display)

DWYER USA DPG-203 Digital Pressure Gauge

Thread : 1/4 NPT Male

Seal Material : Nitrile rubber (NBR)

Outer Size : Approx. 86 mm x 29 mm (casing)

Mount Type : Other, Bottom connection

Grade : Industrial

Glass Size : 2.7 inch display window

DWYER USA DPG-204 Digital Pressure Gauge

Thread : 1/4 NPT male

Seal Material : BunaN

Outer Size : 76 mm diameter approx.

Mount Type : Other, Direct Mount

Grade : Industrial

Glass Size : Digital display, no glass

DWYER USA DPG-209 Digital Pressure Gauge

Thread : 1/4 NPT Male

Seal Material : EPDM Rubber

Outer Size : 76 mm

Mount Type : Other, Bottom Connection

Grade : Industrial

Glass Size : 70 mm

Send Inquiry

Send Inquiry