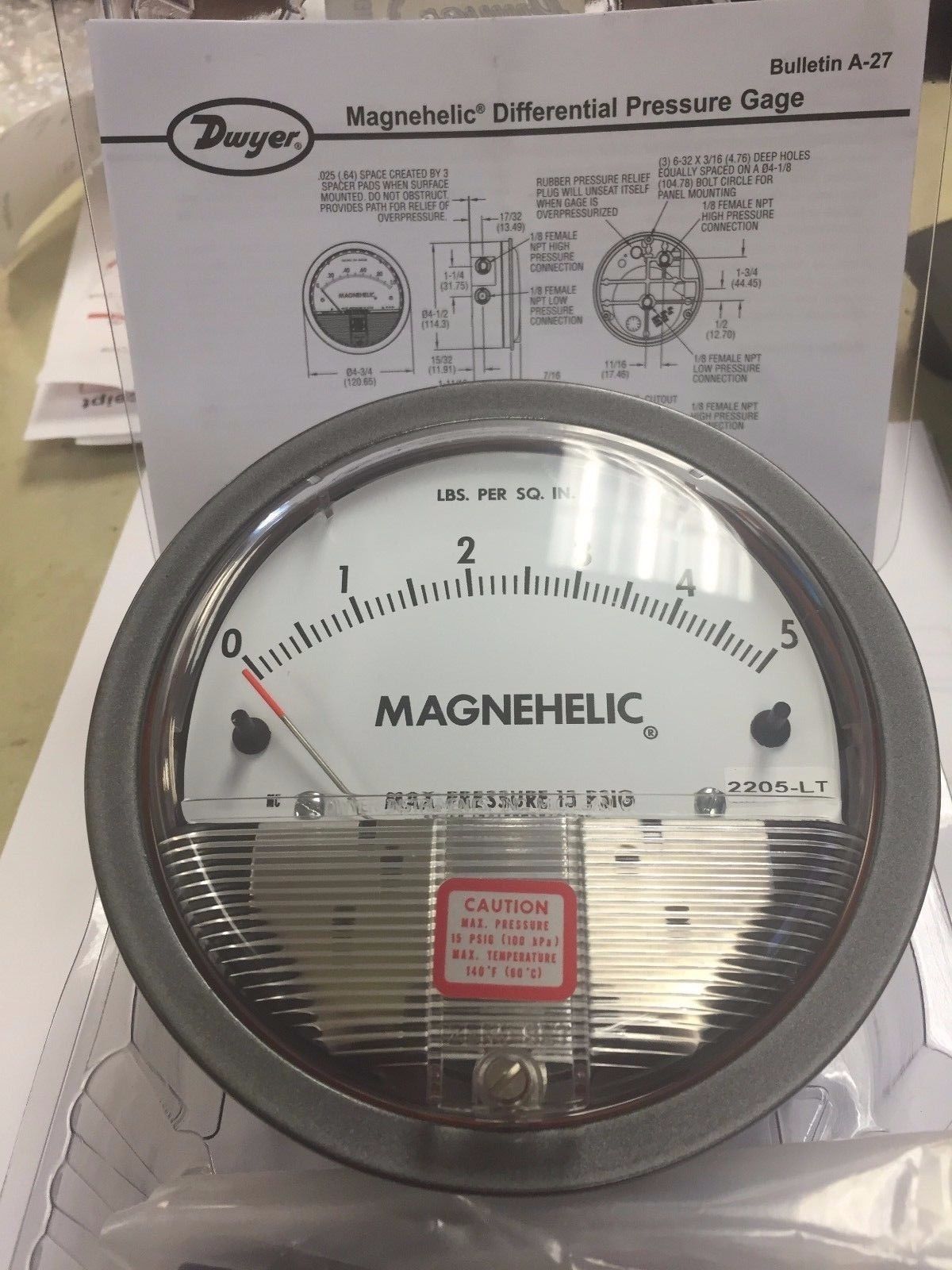

Dwyer USA 2005 Magnehelic Gage Range 0-5.0 Inch WC

Dwyer USA 2005 Magnehelic Gage Range 0-5.0 Inch WC Specification

- Thread

- 1/8 NPT Female

- Outer Size

- Approximately 4 inch (101.6 mm) housing diameter

- Grade

- Industrial Grade

- Seal Material

- Silicone

- Display

- Analog

- Sensor Type

- Diaphragm Sensor

- Material

- Die-cast Aluminum Case, Polycarbonate Window

- Dial Material

- Aluminum, White background

- Pointer Material

- Precision Molded Plastic

- Processing Type

- Precision Mechanical

- Diameter

- 4 inch (101.6 mm)

- Glass Size

- 4 inch (101.6 mm)

- Mount Type

- Surface/Panel Mount

- Scale Range

- 0-5.0 inch WC (Water Column)

- Accuracy

- 2% of Full Scale

- Finishing

- Powder Coated / Anodized Aluminum

- Measure Pressure Of

- Air and Non-corrosive Gases

- Accessories

- Two 1/8 NPT plugs, two self-tapping mounting screws, flush mounting adapter with screws and cup washer, and standard instruction sheet

About Dwyer USA 2005 Magnehelic Gage Range 0-5.0 Inch WC

Dwyer USA 2005 Magnehelic Gage Range 0-5.0 Inch WC

Description

Dwyer 2005 Differential pressure gage, range 0-5.0" w.c. (inches of water), minor divisions .10.

Using Dwyers simple, frictionless Magnehelic Gage movement, it quickly indicates low air or non-corrosive gas pressures--either positive, negative (vacuum) or differential. The design resists shock, vibration and over-pressures. No manometer fluid to evaporate, freeze or cause toxic or leveling problems. Its inexpensive, too.

The Magnehelic Gage is the industry standard to measure fan and blower pressures, filter resistance, air velocity, furnace draft, pressure drop across orifice plates, liquid levels with bubbler systems and pressures in fluid amplifier or fluidic systems. It also checks gas-air ratio controls and automatic valves, and monitors blood and respiratory pressures in medical care equipment.

Note: May be used with Hydrogen. Order a Buna-N diaphragm. Pressures must be less than 35 psi.

Features

Bezel provides flange for flush mounting in panel.

Clear plastic face is highly resistant to breakage. Provides undistorted viewing of pointer and scale.

Precision litho-printed scale is accurate and easy to read.

Red tipped pointer of heat treated aluminum tubing is easy to see. It is rigidly mounted on the helix shaft.

Pointer stops of molded rubber prevent pointer over-travel without damage.

"Wishbone" assembly provides mounting for helix, helix bearings and pointer shaft.

Jeweled bearings are shock-resistant mounted; provide virtually friction-free motion for helix. Motion damped with high viscosity silicone fluid.

Zero adjustment screw is conveniently located in the plastic cover, and is accessible without removing the cover. O-ring seal provides pressure tightness.

Helix is precision made from an alloy of high magnetic permeability. Mounted in jeweled bearings, it turns freely, following the magnetic field to move the pointer across the scale.

Samarium Cobalt magnet mounted at one end of range spring rotates helix without mechanical linkages.

Calibrated range spring is flat spring steel. Small amplitude of motion assures consistency and long life. It reacts to pressure on diaphragm. Live length adjustable for calibration.

Silicone rubber diaphragm with integrally molded O-ring is supported by front and rear plates. It is locked and sealed in position with a sealing plate and retaining ring. Diaphragm motion is restricted to prevent damage due to overpressures.

Die cast aluminum case is precision made and iridite-dipped to withstand 168 hour salt spray corrosion test. Exterior finished in baked dark gray hammerloid. One case size is used for all standard pressure options, and for both surface and flush mounting.

Blowout plug of silicone rubber protects against overpressure on 15 psig rated models. Opens at approximately 25 psig.

O-ring seal for cover assures pressure integrity of case.

Engineered for Precise Low-Pressure Measurement

The Dwyer 2005 Magnehelic Gage ensures high repeatability and accuracy for industrial applications such as duct static pressure, filter monitoring, and clean room pressure control. Built with a reliable diaphragm sensor and providing virtually immediate mechanical response, it is suited for demanding environments where real-time readings are crucial.

Designed for Versatility and Durability

Housed in powder-coated, anodized die-cast aluminum, the Magnehelic gauge features both side and back connections for flexible installation. Its IP52 enclosure and wide operating temperature range allow usage in various climates, while its polycarbonate window guarantees clarity and protection in challenging conditions.

Effortless Installation and User-Friendly Operation

The gauge comes with all necessary accessories for panel or surface mounting, including adapters, screws, and clear instructions. Simple zero adjustment on the front allows quick recalibration, ensuring ongoing precision without hassle. Clear analog display promotes easy reading for users at all levels.

FAQs of Dwyer USA 2005 Magnehelic Gage Range 0-5.0 Inch WC:

Q: How do I install the Dwyer 2005 Magnehelic Gage in my system?

A: The gauge can be mounted on a surface or panel using the included flush mounting adapter, screws, and cup washer. Its side and back threaded 1/8 NPT female connections provide flexibility for plumbing air or non-corrosive gas lines. Refer to the standard instruction sheet for detailed installation steps.Q: What types of applications is this Magnehelic gage suitable for?

A: It is ideal for monitoring filter status, measuring duct or clean room pressure, and indicating fan or blower pressure in HVAC, clean space, and industrial environments. Its precision is especially valuable in applications demanding reliable, low-pressure measurement of air and non-corrosive gases.Q: When should I use the zero adjustment feature?

A: Use the external front zero adjustment screw to recalibrate the pointer to zero when the gauge is not under pressure, ensuring ongoing measurement accuracy. Zero adjustment is recommended after initial installation or following any significant mechanical disturbance.Q: Where can the Dwyer 2005 Magnehelic Gage be installed?

A: With its IP52 rating and operating temperature of -7C to 60C, it can be installed indoors in HVAC systems, clean rooms, or industrial environments where protection from dust and light moisture is needed. Avoid locations with direct liquid exposure beyond the enclosures protection level.Q: What is the benefit of choosing this gauge for filter monitoring?

A: This gauge offers immediate mechanical response and high repeatability (0.1% of span), allowing you to detect filter clogs or airflow changes quickly. The analog scale ensures you can easily spot when maintenance is required, helping prevent system inefficiencies.Q: How accurate are the measurements from this gauge?

A: The Dwyer 2005 Magnehelic Gage provides 2% of full-scale accuracy and a repeatability of 0.1% of span, making it highly reliable for critical low-pressure monitoring tasks.Q: What maintenance does this gauge require for optimal performance?

A: Periodic external zero adjustments and keeping the polycarbonate window clean ensure sustained accuracy. Regularly inspect connections for leaks or blockages. No specialized maintenance is required for the mechanical sensor under typical operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sensocon - Dwyer S2000 Differential Pressure Gauge Category

Dwyer 2000-0AV Magnehelic Differential Pressure Gauge

Minimum Order Quantity : 12 Pieces

Measure Pressure Of : Other, Air and noncorrosive gases

Outer Size : 115 mm diameter approx.

Seal Material : Silicone rubber

Grade : Industrial

Processing Type : Other, Factory calibrated

Dwyer USA Model 2300-0 Magnehelic Gage Range 0.25-0-0.25 Inch WC

Minimum Order Quantity : 12 Pieces

Measure Pressure Of : Other, Air and NonCorrosive Gases

Outer Size : 4 inch (101.6 mm) Diameter

Seal Material : Silicone rubber diaphragm, BunaN seals

Grade : Industrial

Processing Type : Other, Precision Engineered

Dwyer USA Model 2012 Magnehelic Gage Range 0-12 Inch WC

Minimum Order Quantity : 12 Pieces

Measure Pressure Of : Other, Air and compatible gases

Outer Size : 4.75 inch diameter (approx. 120 mm)

Seal Material : Silicone, BunaN

Grade : Industrial Grade

Processing Type : Other, Machined and Assembled

Dwyer USA Model 2040 Magnehelic Gage Range 0-40 Inch WC

Minimum Order Quantity : 12 Pieces

Measure Pressure Of : Other, Air and noncorrosive gases

Outer Size : 4 inches (101.6mm) diameter housing

Seal Material : Silicone rubber

Grade : Industrial

Processing Type : Other, Machined and calibrated

Send Inquiry

Send Inquiry