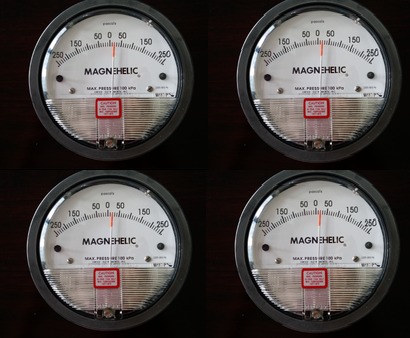

Dwyer USA 2002 Magnehelic Gage Range 0-2.0 Inch WC

Dwyer USA 2002 Magnehelic Gage Range 0-2.0 Inch WC Specification

- Seal Material

- Silicone and Neoprene

- Thread

- 1/8 NPT Rear High and Low Pressure Ports

- Grade

- Industrial Grade

- Display

- Analog Dial

- Outer Size

- 4 inch (101.6 mm) diameter

- Bourdon Tube

- Not Applicable (Diaphragm Sensing Element)

- Sensor Type

- Differential Pressure Sensor

- Material

- Die-cast aluminum case; acrylic lens

- Dial Material

- Acrylic

- Pointer Material

- Aluminum

- Processing Type

- Factory Calibrated and Tested

- Diameter

- 4 inch (101.6 mm)

- Glass Size

- 4 inch (dial window)

- Mount Type

- Surface or Flush Mount

- Scale Range

- 0-2.0 Inch WC (Water Column)

- Accuracy

- 2% of Full Scale

- Finishing

- Black baked enamel case finish

- Measure Pressure Of

- Air and non-corrosive gases

- Accessories

- Two 1/8 NPT plugs, two 1/8 pipe thread to rubber tubing adapters, three flush mounting adapters and screws

Dwyer USA 2002 Magnehelic Gage Range 0-2.0 Inch WC Trade Information

- Minimum Order Quantity

- 12 Pieces

- Main Domestic Market

- All India

About Dwyer USA 2002 Magnehelic Gage Range 0-2.0 Inch WC

Dwyer USA 2002 Magnehelic Gage Range 0-2.0 Inch WC

Filter Monitoring

Air Velocity with Dwyer Pitot Tube

- Blower Vacuum Monitoring

Fan Pressure Indication

Duct, Room or Building Pressures

Clean Room Positive Pressure Indication

Select the Magnehelic Gage for high accuracy--guaranteed within 2% of full scale--and for the wide choice of models available to suit your needs precisely. Using Dwyers simple, frictionless Magnehelic Gage movement, it quickly indicates low air or non-corrosive gas pressures--either positive, negative (vacuum) or differential. The design resists shock, vibration and over-pressures. No manometer fluid to evaporate, freeze or cause toxic or leveling problems. Its inexpensive, too.

The Magnehelic Gage is the industry standard to measure fan and blower pressures, filter resistance, air velocity, furnace draft, pressure drop across orifice plates, liquid levels with bubbler systems and pressures in fluid amplifier or fluidic systems. It also checks gas-air ratio controls and automatic valves, and monitors blood and respiratory pressures in medical care equipment.

Specifications

Service: Air and non-combustible, compatible gases (Natural Gas option available).

Wetted Materials: Call us at 9871034100 Mail -envirotech76@yahoo.co.in

Housing: Die cast aluminum case and bezel, with acrylic cover. Exterior finish is coated gray to withstand 168 hour salt spray corrosion test.

Accuracy: 2% of full scale throughout range at 70F (21.1C).

Pressure Range: 0-1.0" w.c.

Pressure Limits: -20" Hg. to 15 psig. (-0.677 bar to 1.034 bar).

Overpressure: Relief plug opens at approximately 25 psig (1.72 bar), standard gages only.

Temperature Limits: 20 to 140F (-6.67 to 60C).

Mounting Orientation: Diaphragm in vertical position.

Process Connections: 1/8" female NPT duplicate high and low pressure taps - one pair side and one pair back.

Weight: 1 lb 2 oz (510 g).

Standard Accessories: Two 1/8" NPT plugs for duplicate pressure taps, two 1/8" pipe thread to rubber tubing adapters and three flush mounting adapters with screws.

High Accuracy Differential Pressure Monitoring

The Dwyer 2002 Magnehelic Gage provides reliable differential pressure readings with a fine 0.05 inch WC scale graduation and 2% full-scale accuracy. Designed for both industrial and commercial applications, it ensures precise monitoring of air or non-corrosive gases, making it suitable for systems where maintaining accurate pressure control is essential.

Durable Design and Easy Calibration

Constructed from die-cast aluminum with an acrylic lens, the gage is resistant to corrosion and physical impacts. An external front adjustment screw allows for simple zero calibration, ensuring ongoing accuracy without dismantling. The cases IP54 rating defends against dust and moisture, enhancing longevity even in challenging environments.

Flexible Installation and Immediate Response

The gage supports both flush and surface mounting, with a vertical orientation as standard. Back ports fit 1/8 NPT connections, and accessories are included for adaptable setup. Its mechanical movement guarantees immediate response to pressure variations, supporting critical monitoring needs in HVAC, filtration, or process control.

FAQs of Dwyer USA 2002 Magnehelic Gage Range 0-2.0 Inch WC:

Q: How is the Dwyer 2002 Magnehelic Gage typically installed?

A: The gauge can be surface or flush mounted, with a standard vertical orientation. It comes with the necessary adapters, screws, and plugs for straightforward installation. Rear high and low pressure ports accept 1/8 NPT connections for easy integration into most systems.Q: What types of pressure media are suitable for this gauge?

A: The Dwyer 2002 Magnehelic Gage is designed for use with air or compatible clean, non-corrosive gases only. Using unauthorized gases or liquids may damage the sensing element and compromise measurement accuracy.Q: When should I recalibrate the Magnehelic Gage?

A: Regular calibration is recommended to maintain accuracy, particularly if the gauge is exposed to harsh conditions or after prolonged use. Calibration can be done externally via the front adjustment screw without disassembly, ensuring reliable ongoing performance.Q: Where can the Magnehelic Gage be used most effectively?

A: This gauge is ideal for monitoring differential air pressures in HVAC systems, clean rooms, air filter monitoring, and process control environments where air or clean gases are present, particularly in industrial facilities across India.Q: What are the benefits of the Magnehelic Gages immediate response time?

A: Its mechanical movement and diaphragm sensing element provide instant indication of pressure changes, enabling prompt detection of system issues or maintenance needs. This responsiveness is crucial in applications where timely pressure monitoring is essential.Q: How does the external zero adjustment feature improve usage?

A: The external adjustment screw allows users to easily recalibrate the gauge without opening the enclosure, streamlining routine maintenance and minimizing downtime for critical operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sensocon - Dwyer S2000 Differential Pressure Gauge Category

Dwyer 2300-250PA Differential Pressure Gage Range 125-0-125 Pa

Price 4800 INR

Minimum Order Quantity : 12 Pieces

Seal Material : Silicone Rubber (internal)

Diameter : Approx. 41/4 inch (108 mm)

Glass Size : Acrylic Cover approx. 4 inch

Thread : No Thread (Connection through Pressure Ports)

Dwyer 2000-250PA Magnehelic Differential Pressure Gauge

Price 3500 INR

Minimum Order Quantity : 12 Pieces

Seal Material : BunaN

Diameter : 4.5 inches (115 mm)

Glass Size : 110 mm (approx.)

Thread : 1/8 NPT female (high and low pressure ports)

Dwyer 2203 Magnehelic Differential Pressure Gauge 0-3 PSI

Minimum Order Quantity : 12 Pieces

Seal Material : Silicone rubber

Diameter : 4 inch (101.6 mm)

Glass Size : Clear acrylic lens

Thread : 1/8 NPT Female Connection

Dwyer USA Model 2060 Magnehelic Gage Range 0-60 Inch WC

Minimum Order Quantity : 12 Pieces

Seal Material : Silicone Rubber

Diameter : 41/2 inch

Glass Size : 4 inch (Acrylic Lens)

Thread : 1/8 NPT

Send Inquiry

Send Inquiry