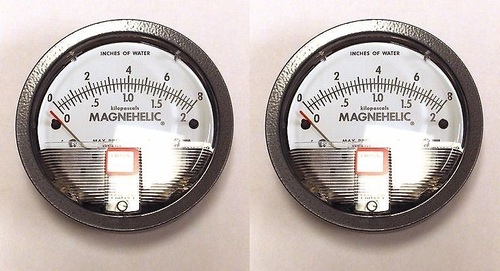

Dwyer 2000-100PA Magnehelic Differential Pressure Gauge

Dwyer 2000-100PA Magnehelic Differential Pressure Gauge Specification

- Thread

- 1/8 NPT (female) high and low pressure connections

- Outer Size

- Standard 4 (101.6 mm) diameter

- Grade

- Industrial Grade

- Seal Material

- Silicone rubber

- Display

- Analog

- Sensor Type

- Diaphragm

- Material

- Case: Die-cast aluminum

- Dial Material

- White aluminum with black markings

- Pointer Material

- Red-tipped aluminum

- Processing Type

- Mechanical

- Diameter

- Approximately 115 mm (including flange)

- Glass Size

- Clear acrylic, approximately 100 mm

- Mount Type

- Surface (flush) or panel mounting

- Scale Range

- 0-100 Pa

- Accuracy

- 2% of full scale

- Finishing

- Textured black casing, clear acrylic cover

- Measure Pressure Of

- Air and non-corrosive gases

- Accessories

- Two 1/8 NPT pipe plugs for duplicate pressure taps, two flush mounting adapters, and screws

Dwyer 2000-100PA Magnehelic Differential Pressure Gauge Trade Information

- Minimum Order Quantity

- 12 Pieces

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Main Export Market(s)

- Australia, South America, Middle East, Western Europe, Africa, Asia, Eastern Europe, North America

- Main Domestic Market

- All India

About Dwyer 2000-100PA Magnehelic Differential Pressure Gauge

Dwyer 2000-100PA Magnehelic Differential Pressure Gauge

Series 2000 Magnehelic Differential Pressure Gage, 0-100 Pa, Minor Divisions 2.0, Vertical

Indicate Positive, Negative or Differential

Select the Magnehelic gage for high accuracy-guaranteed. Using Dwyers simple, frictionless Magnehelic gage movement, it quickly indicates low air or non-corrosive gas pressures. The design resists shock, vibration and over-pressures. No manometer fluid to evaporate, freeze or cause toxic or leveling problems. Its inexpensive, too.

The Magnehelic gage is the industry standard to measure fan and blower pressures, filter resistance, air velocity, furnace draft, pressure drop across orifice plates, liquid levels with bubbler systems and pressures in fluid amplifier or fluidic systems. It also checks gas-air ratio controls and automatic valves, and monitors blood and respiratory pressures in medical care equipment.

Product Applications

Approvals

Features

Specification

| Service | Air and non-combustible, compatible gases |

| Housing | Die cast aluminum case and bezel, with acrylic cover, Exterior finish is coated gray to withstand 168 hour salt spray corrosion test |

| Pressure Limits | -20 in Hg. to 15 psig. (-0.677 bar to 1.034 bar) |

| Overpressure | Relief plug opens at approximately 25 psig (1.72 bar), standard gages only |

| Temperature Limits | 20 to 140F |

| Mounting Orientation | Diaphragm in vertical position |

| Process Connections | 1/8" female NPT duplicate high and low pressure taps - one pair side and one pair back |

| Weight | 1 lb 2 oz (510 g) |

| Standard Accessories | Two 1/8" NPT plugs for duplicate pressure taps, two 1/8" pipe thread to rubber tubing adapters and three flush mounting adapterswith screws |

| Agency Approval | RoHS |

| Accuracy | 3% |

| Size | 4" (101.6 mm) diameter dial face |

Robust Precision for Industrial Environments

Designed for reliability, the Dwyer 2000-100PA gauge features a die-cast aluminum case, textured black finish, and a dust-tight front lens. It delivers stable and highly accurate readings, even with fluctuating back pressure, thanks to its low hysteresis and robust diaphragm sensor. The clear acrylic cover and easy external zero adjustment add to its industrial appeal.

Versatile Applications and Easy Installation

Engineered for HVAC systems, cleanrooms, and filter monitoring, the gauge measures air and non-corrosive gases easily. Its compact, standard 4-inch diameter allows panel or flush mounting, while side-located 1/8 NPT ports and provided accessoriespipe plugs, adapters, screwssimplify the installation process in varied environments.

FAQs of Dwyer 2000-100PA Magnehelic Differential Pressure Gauge:

Q: How do I install the Dwyer 2000-100PA Magnehelic Differential Pressure Gauge?

A: The gauge can be surface (flush) or panel-mounted using the provided adapters and screws. Connect your high and low pressure lines to the side 1/8 NPT (female) ports. It comes with additional pipe plugs for duplicate pressure taps, ensuring flexible integration into HVAC or industrial monitoring systems.Q: What types of gases can be measured with this gauge?

A: This Magnehelic gauge is calibrated to measure the differential pressure of air and non-corrosive gases. It is not suitable for liquid measurements or corrosive gas applications, ensuring safe use in common environmental and filtration processes.Q: When should I adjust the zero on the gauge, and how is it done?

A: Zero adjustment is recommended before initial operation and periodically, especially after mechanical shocks or significant environmental changes. The external screw provides easy, tool-assisted zeroing to maintain accuracy within 2% of full scale.Q: Where is this gauge best utilized in HVAC or cleanroom settings?

A: Install the Dwyer 2000-100PA on filter housings, across ducts, or within cleanrooms to monitor pressure drop or maintain controlled air flow. Its dust-tight front and robust build are designed for demanding locations, ensuring reliable long-term monitoring.Q: What are the key benefits of using this pressure gauge over digital models?

A: Its mechanical, analog operation provides instantaneous, stable readings without requiring power. Low hysteresis (typically <1% FS) and straightforward zero adjustment yield consistent performance, particularly for continuous system monitoring in industrial and commercial applications.Q: How does the gauge maintain stable readings in environments with fluctuating pressure?

A: Thanks to its diaphragm sensor and mechanical design, the gauge provides stable, easy-to-read outputs even with rapidly changing back pressure, making it suitable for dynamic HVAC or filtration systems requiring precise pressure control.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sensocon - Dwyer S2000 Differential Pressure Gauge Category

Dwyer 2008D Magnehelic Differential Pressure Gauge

Minimum Order Quantity : 12 Pieces

Diameter : 114 mm (4.5 inches)

Display : Analog

Finishing : Other, PowderCoated Housing

Grade : Industrial Grade

Seal Material : Silicone Rubber

Dwyer USA Model 2300-0 Magnehelic Gage Range 0.25-0-0.25 Inch WC

Minimum Order Quantity : 12 Pieces

Diameter : 4 inch (101.6 mm)

Display : Analog

Finishing : Other, Corrosion Resistant DieCast Aluminum Case, Painted

Grade : Industrial

Seal Material : Silicone rubber diaphragm, BunaN seals

Dwyer 2015D Magnehelic Differential Pressure Gauge

Minimum Order Quantity : 12 Pieces

Diameter : 115 mm (4.5 inch)

Display : Analog Dial

Finishing : Other, Powder Coated / DieCast Finish

Grade : Industrial Grade

Seal Material : Silicone / Neoprene

Dwyer 2300-4CM Magnehelic Differential Pressure Gauge Range 2-0-2 CM

Minimum Order Quantity : 12 Pieces

Diameter : 4 inches (approx. 100 mm)

Display : Analog

Finishing : Other, Powder coated

Grade : Industrial

Seal Material : Silicone rubber

Send Inquiry

Send Inquiry