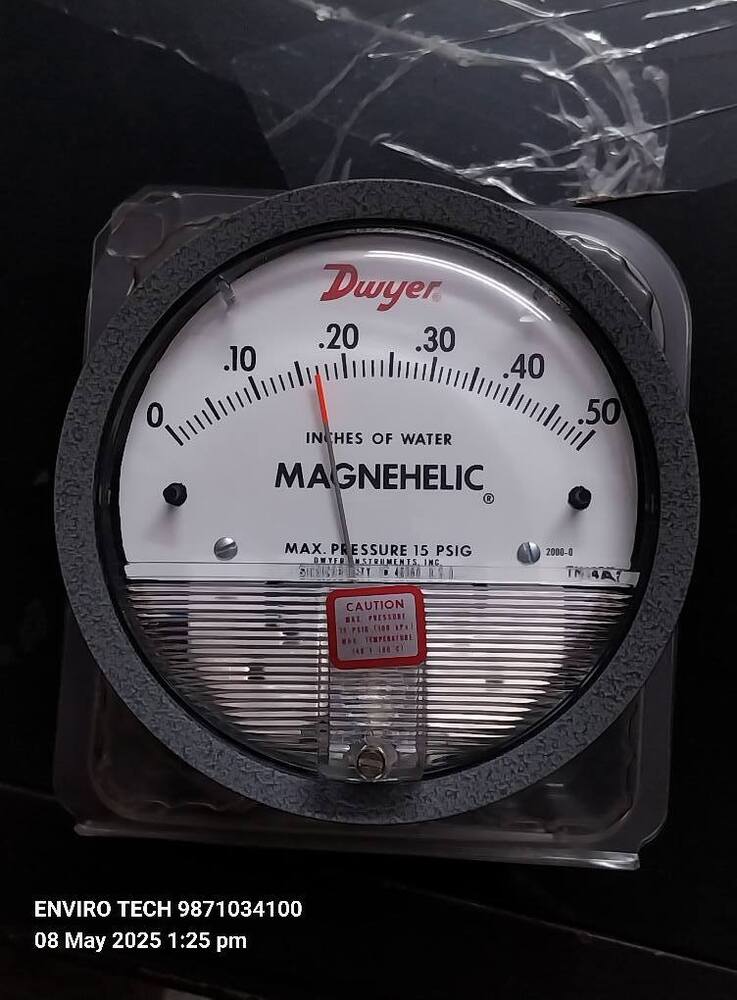

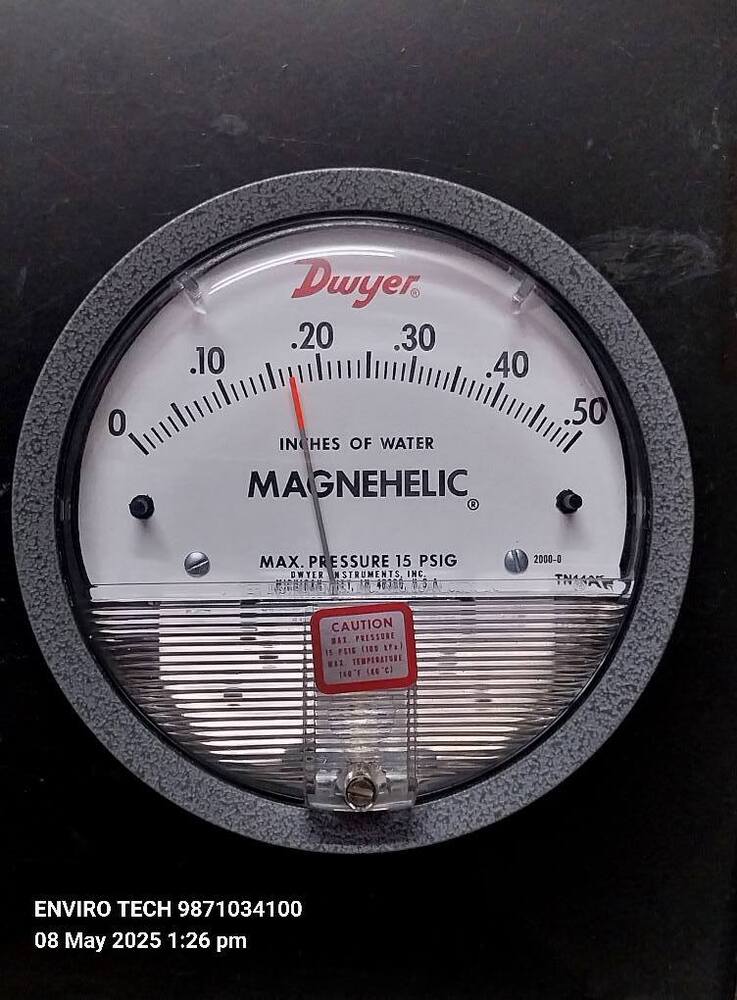

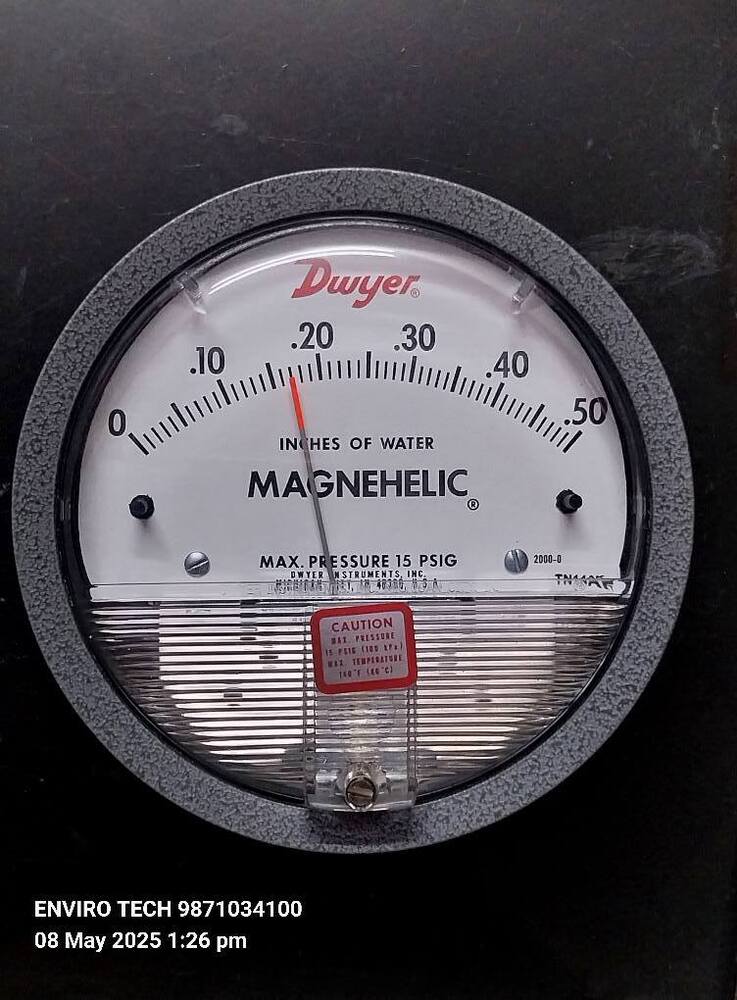

DWYER 2000-0 Magnehelic Differential Pressure Gauge Range 0-0.5 Inch WC

Price 13500 INR/ Piece

DWYER 2000-0 Magnehelic Differential Pressure Gauge Range 0-0.5 Inch WC Specification

- Thread

- 1/8" female NPT duplicate high and low pressure taps - one pair side and one pair back

- Display

- Analog

- Material

- Metal Alloy

- Usage

- Pharmaceutical,POWER PLANT,CEMENT PLANT,STEEL PLANT,FERTILIZER,TEXTILE

- Dial Material

- Plastic

- Pointer Material

- Alloy

- Size

- 4" (101.6 MM) Diameter Dial Face.

- Processing Type

- Standard

- Diameter

- 4 inch / 100 MM Millimeter (mm)

- Product Type

- DWYER 2000-0 Magnehelic Differential Pressure Gauge Range 0-0.5 Inch WC

- Weight

- 550 Grams (g)

- Color

- WHITE / BLACK

- Mount Type

- Back

- Scale Range

- MM WC/ CM / PAC / KPA / INCH / PSI / MBAR

- Accuracy

- 2% (-HA model 1) of FS (3% (-HA 1.5%) on -0, -100PA, -125PA, -10MM and 4% (-HA 2%) on -00, -60PA, -6MM Ranges), Throughout Range at 70F (21.1C).

DWYER 2000-0 Magnehelic Differential Pressure Gauge Range 0-0.5 Inch WC Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Delhi

- Payment Terms

- Paypal, Cash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Cheque, Days after Acceptance (DA), Delivery Point (DP), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Western Union, Letter of Credit (L/C)

- Packaging Details

- EXTRA

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- YAS

About DWYER 2000-0 Magnehelic Differential Pressure Gauge Range 0-0.5 Inch WC

DWYER 2000-0 Magnehelic Differential Pressure Gauge Range 0-0.5 Inch WC

SPECIFICATION

- Ambient Temperature- -21 140 -6 60

- Rated Pressure-20 inHg30 inHg (-68103KPa)

- Overpressure -Protective rubber stopper will be blown out if rated pressure is up to about 50.8 inHg (172KPa)

- Process Connections -1/8" Female NPT Duplicate High And Low Pressure Taps - One Pair Side And One Pair Back

- Housing- Die cast aluminum case and bezel, with acrylic cover,Exterior finish is coated gray to withstand168 Hour Salt Spray Corrosion Test

- Accuracy- 2% of full span at 70 (21 (3% on -0, and 4% on -00)

- Range-20 inHg38 inHg (-68KPa130KPa)(Special Specification also can be ordered.

FEATURES

- OEM/ODM

- There Is No Need To Fill Liquid To Gauge.

- The Gauge Can Measure Positive Pressure,Negative Pressure And Differential Pressure.

- It Will Be Easy To Install And Measure In Different Ways Because Of Two Groups Of Ports Which Can Measure Positive AndNegative Pressure.

- To Eliminate The Friction From The Movement Of Gear Wheel By The Mechanism Of Magnetic Magnet Feed.

- Exact And Stable Fixed Position Of Needle.

- The Gauge Has Great Antiknock Characteristics.

- There Are 81 Types Of Ranges.Minimum is 0-60 Pa And Maximum is 0-21-KPa

PRODUCT APPLICATIONS

- Filter Monitoring

- Air Velocity With Pitot Tube

- Blower Vacuum Monitoring

- Fan Pressure Indication

- Duct,Room or Building Pressures

- Clean Room Positive Pressure Indication

MODELS & ORDERING

DWYER ByModel NumberPopularity

- FILTER BY

- Range - Inches of Water

|

Model |

Description |

|

2000-0 |

Differential Pressure Gauge,Range 0-0.50 w.c., minor divisions .01, calibrated for vertical scale position. |

|

2000-00 |

Differential Pressure Gauge,Range 0-0.25 w.c.,minor divisions .005, calibrated for vertical scale position. |

|

2001 |

Differential Pressure Gauge,Range 0-1.0 w.c.,minor divisions .02. |

|

2002 |

Differential Pressure Gauge,Range 0-2.0 w.c.,minor divisions .05. |

|

2003 |

Differential Pressure Gauge,Range 0-3.0 w.c.,minor divisions .10. |

|

2004 |

Differential Pressure Gauge,Range 0-4.0 w.c.,minor divisions .10. |

|

2005 |

Differential Pressure Gauge,Range 0-5.0 w.c.,minor divisions .10. |

|

2006 |

Differential Pressure Gauge,Range 0-6.0 w.c., minor divisions .20. |

Additional Information:

- Item Code:DWYER 2000-0 Magnehelic Differential Pressure Gauge Range 0-0.5 Inch WC

- WhatsApp No.9871034100,9868958924,9650264867,9716640145,8368866030,8368801023

- www.envirotechdelhi.net

- www.envirotechindia.info

- www.envirotechdelhi.info

Precision and Versatility

Designed for a variety of industrial applications, the DWYER 2000-0 Magnehelic Differential Pressure Gauge provides accurate readings across multiple scale types. Regardless of whether you require metrics in inches of water column, millibar, or PSI, this instrument adapts to your needs and delivers reliable results every time.

Durability and Robust Construction

Constructed from high-quality metal alloy with a durable plastic dial, this gauge is built to withstand rigorous environments such as power, steel, cement, fertilizer, and textile plants. Its sturdy materials and back-mount versatility make it a long-lasting solution for continuous operation in both indoor and outdoor settings.

User-Friendly Design

The 4-inch analog dial offers exceptional visibility, making pressure readings straightforward even in low-light conditions. The inclusion of side and back NPT taps ensures easy setup, while the lightweight design (550 grams) allows for flexible mounting without extra support.

FAQs of DWYER 2000-0 Magnehelic Differential Pressure Gauge Range 0-0.5 Inch WC:

Q: How do I install the DWYER 2000-0 Magnehelic Differential Pressure Gauge?

A: Installation is straightforward with both side and back 1/8" female NPT pressure taps. Simply connect the high and low pressure lines to the designated taps, mount the gauge using the back mount option, and ensure it is positioned for easy dial visibility. Detailed instructions are provided in the user manual.Q: What scale ranges are available on this pressure gauge?

A: This gauge is equipped with multiple scale ranges, including MM WC, CM, KPA, INCH, PSI, MBAR, and PAC. This flexibility allows users to take measurements in their preferred or required units for various applications.Q: When is it recommended to use this pressure gauge?

A: The DWYER 2000-0 is ideal for continuous differential pressure monitoring in critical processes across pharmaceutical facilities, power plants, steel manufacturing, cement production, fertilizer units, and textile operations. Use it whenever precise pressure monitoring ensures operational safety and process efficiency.Q: Where can this gauge be installed?

A: It is suitable for installation in industrial environments such as control rooms, equipment panels, and on-site processing stations. Its durable construction allows it to perform reliably in both clean and rugged industrial areas.Q: What is the process for taking a pressure reading with the Magnehelic Gauge?

A: To take a measurement, connect the high and low pressure sources to the corresponding taps. The pressure difference is then indicated by the analog pointer on the large, easy-to-read dial. No electrical power is needed, and readings are instantaneous.Q: How does this gauge benefit industrial facilities?

A: With a high accuracy of 2% of full scale and a robust build, the gauge enables operators to monitor pressure variations efficiently, helping diagnose blockages, leaks, or system inefficiencies promptly. This supports preventive maintenance and improves overall plant safety and productivity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in DWYER I INSTRUMENTS SERIES 2000 MAGNEHELIC DIFFERENTIAL PRESSURE GAUGE INCHES OF WATER Category

DWYER 2000-0 Magnehelic Differential Pressure Gauge 2000 Range 0-0.5 Inch WC

Price 13500 INR / Piece

Minimum Order Quantity : 1 Piece

Mount Type : Back

Usage : Pharmaceutical,POWER PLANT,CEMENT PLANT,STEEL PLANT,FERTILIZER,TEXTILE

Size : 4" (101.6 MM) Diameter Dial Face.

Measure Pressure Of : Gas

Send Inquiry

Send Inquiry