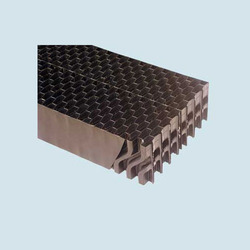

Drift Eliminator

Drift Eliminator Specification

- Application

- Cooling towers, HVAC systems, industrial water cooling

- Air Flow

- High efficiency

- Material

- PVC (Polyvinyl Chloride)

- Condition

- New

- Type

- Drift Eliminator

- Dimension (L*W*H)

- Custom sizes available as per cooling tower design

- Cooling Type

- Water Cooling Tower

- Water Flowing Rate

- Optimized for minimal drift loss

- Noise Control

- Minimized drift for reduced noise

About Drift Eliminator

- Reduces Carry over loss of water

- Made of rigid PVC (Applicable of Square type cooling towers)

- Shape : S Type

- Size : 600mm x 600mm x 120mm

- Color : Black

We have become the topnotch entity of the industry by manufacturing and supplying best quality range of Drift Eliminator. This water cooling device is manufactured by our trusted vendors of the market using highest quality materials in compliance with quality standards set by the industry. This Drift Eliminator controls the water loss from a cooling tower by controlling the amount of circulated water droplets emitted with exhaust air of the tower.

Features:

- Longer life span

- Superb durability

- Excellent finishing

Advanced Drift Elimination Efficiency

Utilizing a cellular design and precisely profiled fins, this drift eliminator achieves outstanding drift loss reduction while maintaining high airflow. Its optimized packing density ensures maximum air-water separation, leading to significant water and noise reduction benefits in your cooling solution installation.

Durable and Versatile for Any Environment

Built from UV-stabilized, corrosion-resistant PVC, this drift eliminator is suitable for harsh environments and outdoor use. Its gray or black color selection pairs well with modern facility aesthetics. Temperature resistance up to 60C enables reliable operation across various industrial applications.

Effortless Maintenance and Installation

Designed as modular sections, this drift eliminator is both lightweight and easy to handle. Removal, cleaning, and reinstallation require minimal effort, saving maintenance time and reducing system downtime. Custom sizing ensures compatibility with diverse cooling tower configurations.

FAQs of Drift Eliminator:

Q: How does the drift eliminator help reduce water loss in cooling towers?

A: The drift eliminator features a cellular structure and aerodynamically profiled fins that capture water droplets from the air stream, reducing drift loss to less than 0.005% of circulated water. This efficient design minimizes wasted water and supports sustainable operations.Q: What makes the installation and maintenance process straightforward for this drift eliminator?

A: Installation is simplified by the modular, lightweight sections, which can be easily handled, removed, and cleaned. The design reduces maintenance requirements and allows for quick servicing, minimizing system downtime and increasing operational convenience.Q: When should the drift eliminator be replaced or serviced?

A: Under standard operating conditions, this drift eliminator delivers a service life of more than five years. Routine checks and periodic cleaning are recommended to maintain optimal efficiency, but frequent replacement is generally unnecessary due to its robust construction.Q: Where can this drift eliminator be utilized effectively?

A: It is suitable for installations in cooling towers, industrial water cooling systems, and HVAC applications. Its corrosion and UV resistance make it ideal for both indoor and outdoor environments, including harsh industrial or commercial settings.Q: What are the benefits of choosing a modular and customized drift eliminator?

A: Modular sections allow for flexible installation and prompt maintenance, while customization ensures a precise fit for diverse tower sizes and airflow needs. This leads to improved drift control, system performance, and long-term durability tailored to your specific requirements.Q: How does this product contribute to noise reduction in cooling systems?

A: By minimizing drift loss and optimizing water-air separation, the drift eliminator helps reduce turbulence and associated noise levels in cooling tower operation, facilitating quieter performance in sensitive environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cooling Tower Parts Manufacturers Wholesalers Category

Cooling Tower Sprinkler with Distribution Pipe

Material : Other , Aluminum Alloy Sprinkler Head, Mild Steel/HDPE Distribution Pipe

Type : Rotary Sprinkler with Pipe

Condition : New

Application : Industrial Cooling Towers, HVAC, power plants, process industries

Noise Control : Silent Operation (No fan noise)

Cooling Type : Water Evaporative

Cooling Tower Motor

Material : Industrialgrade material likely metal, Other

Type : Industrial Motor

Condition : New

Application : Cooling Towers

Noise Control : Moderate

drift- eliminator

Material : Other , PVC (Polyvinyl Chloride)

Type : Drift Eliminator

Condition : New

Application : Cooling Towers, HVAC Systems, Air Scrubbers

Noise Control : Yes, enhances noise reduction

Cooling Type : Evaporative / Air Cooling

cooling-tower-spare-part

Material : Plastic Metal, Other

Type : Cooling Tower Spare Parts

Condition : New

Application : Cooling Tower Spare Parts

Cooling Type : Forced Draft / Induced Draft

Send Inquiry

Send Inquiry