Digihelic II Differential Pressure Controller

Digihelic II Differential Pressure Controller Specification

- Outer Size

- 110 mm x 110 mm x 69 mm (approx)

- Grade

- Industrial

- Sensor Type

- Differential Pressure Sensor

- Thread

- 1/8 NPT (Female)

- Seal Material

- EPDM Rubber (Gasket)

- Display

- 4-Digit 7-segment LED

- Material

- ABS Plastic, Polycarbonate

- Processing Type

- Microcontroller Based

- Diameter

- Approx. 110 mm front bezel

- Mount Type

- Panel/Surface Mount

- Scale Range

- 0-1000 Pa (other ranges available)

- Accuracy

- 1% of F.S.

- Finishing

- ABS Plastic housing with grey finish

- Measure Pressure Of

- Air & Non-corrosive gases

- Accessories

- Mounting Bracket, Instruction Manual, Power Cable

Digihelic II Differential Pressure Controller Trade Information

- Payment Terms

- Cash on Delivery (COD), Cash Advance (CA), Cash Against Delivery (CAD), Cash in Advance (CID), Cheque

- Main Export Market(s)

- Australia, North America, Eastern Europe, Africa, Central America, Middle East, South America, Western Europe, Asia

- Main Domestic Market

- All India

About Digihelic II Differential Pressure Controller

Digihelic II Differential Pressure Controller Product Details: Brand dwyer SPDT control relays Two Output range 4-20 mA Display type LCD display Product type Pressure Controller The Digihelic Controller just got better with the New Series DHII Differential Pressure Controller. The DHII takes all the fabulous features of the standard Digihelic Pressure Controller and packages them in a robust NEMA 4 (IP66) housing. The Digihelic II Pressure Controller combines the 2 SPDT control relays, process output and Modbus communications with a large, brightly backlit 4 digit LCD display that can easily be seen from long distances. The electrical wiring has also been enhanced in the DHII with its detachable terminal blocks. The removable terminals allow the install to easily wire the terminal block outside the housing and then attach to the circuit board, reducing wiring difficulties and installation time on the process. The Digihelic II Differential Pressure Control in the new NEMA 4 (IP66) enclosure enables this product to be the perfect choice when mounting pressure controls outdoors in such applications as rooftop air handlers. This housing also makes it the ideal solution for surface mounting in clean rooms or facilities where water or a cleaning solution is utilized in maintaining plant cleanliness. Applications: Air Handlers Clean RoomsPrecision Monitoring and Control

With a 1 Pa resolution and 1% full-scale accuracy, the Digihelic II delivers highly reliable differential pressure measurements. The microcontroller-based design enables precise set point and dead band configuration, ensuring optimal process control for air movement and filtration systems.

Flexible Outputs and Versatile Installation

Equipped with two SPDT relay contacts (230VAC/5A) and an optional 4-20 mA analog output, this controller integrates smoothly with diverse industrial automation set-ups. Its compact ABS housing and dual mount options simplify installation, while the IP54 front panel withstands rigorous operating conditions.

FAQs of Digihelic II Differential Pressure Controller:

Q: How do I install the Digihelic II Differential Pressure Controller?

A: The Digihelic II can be mounted on a panel or surface using the included mounting bracket. Ensure the front panel faces outward and connect the electrical wiring via the terminal block as detailed in the instruction manual for safe setup.Q: What pressure range does the Digihelic II measure, and can it be configured for other ranges?

A: The standard model measures differential pressures from 0 to 1000 Pa. However, other measurement ranges are available upon request to suit a variety of application requirements.Q: When should I use the time delay and dead band functionalities?

A: Time delay and dead band features are crucial for applications that require stable control, helping avoid frequent relay switching due to transient pressure fluctuations. Adjust these parameters according to your process dynamics for optimal system performance.Q: Where is the Digihelic II typically used?

A: This controller is widely used in HVAC systems, cleanrooms, filter monitoring, and other industrial environments where accurate control of air or non-corrosive gas pressures is necessary.Q: What output options are available and how can they be used?

A: It provides two SPDT relay outputs rated at 230VAC/5A for alarm or control purposes. An optional 420 mA analog output enables integration with PLCs or remote monitoring systems.Q: What are the operating and storage temperature limits for this device?

A: Operationally, it functions reliably between 0C to +50C, and can be safely stored in environments ranging from -20C to +70C.Q: What benefits do users receive from its microcontroller-based processing?

A: Microcontroller processing ensures high-precision readings, advanced control logic, and consistent device reliability, enhancing overall process efficiency and reducing maintenance needs.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

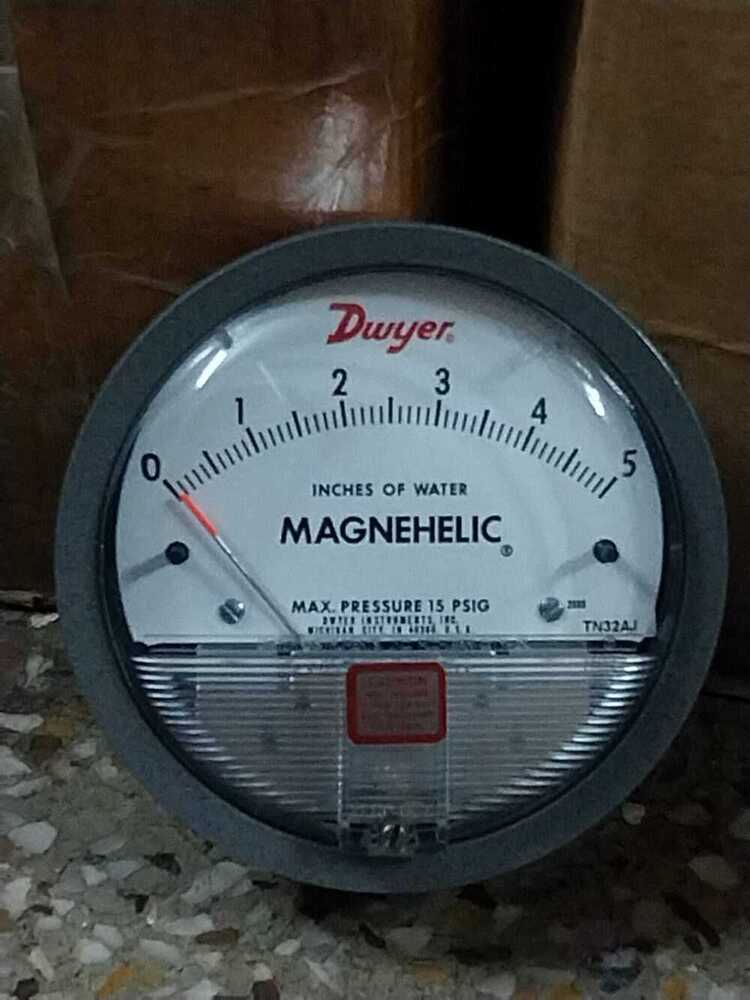

More Products in Dwyer Sensocon USA Magnehelic Gauge wholesaler Category

DWYER Magnehelic Gauge From Baikampandy Industrial Area Karnataka

Price 7500 INR / Piece

Minimum Order Quantity : 1 Piece

Display : Analog

Dial Material : Plastic

Pointer Material : Alloy

Processing Type : Standard

Dwyer Magnehelic Gauge In Beed Maharashtra

Price 5800.00 INR / Piece

Minimum Order Quantity : 1 Piece

Display : Analog

Dial Material : Plastic

Pointer Material : Alloy

Processing Type : Standard

Dwyer Magnehelic Gauge In Pithampur Madhya Pradesh

Price 5800 INR / Piece

Minimum Order Quantity : 1 Piece

Display : Analog

Dial Material : Plastic

Pointer Material : Alloy

Processing Type : Standard

DWYER Magnehelic Gauge From Yeyyadi Industrial Area Karnataka

Price 7500 INR / Piece

Minimum Order Quantity : 1 Piece

Display : Analog

Dial Material : Plastic

Pointer Material : Alloy

Processing Type : Standard

Send Inquiry

Send Inquiry