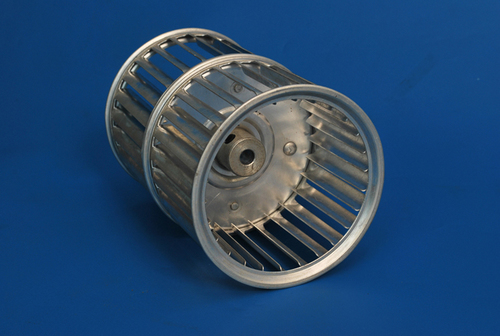

DIDW Centrifugal Fan 151 MM X 100 MM

DIDW Centrifugal Fan 151 MM X 100 MM Specification

- Usage & Applications

- Ventilation, HVAC systems, Air Handling Units

- Temperature

- -20C to +60C

- Air Flow

- 300-900 m/h

- Efficiency

- 85%

- Orientation

- Double Inlet, Double Width

- Automation Grade

- Manual

- Power Source

- Electric

- Product Type

- Centrifugal Fan

- Material

- Mild Steel

- Cooling System

- Air Cooling

- Noise Level

- Low (<70 dB)

- Capacity

- 300-900 m/h

- Voltage

- 220-240 V

- Weight

- Approx. 6.5 kg

- Dimension (L*W*H)

- 151 mm x 100 mm x 200 mm

- Surface

- Powder Coated

DIDW Centrifugal Fan 151 MM X 100 MM Trade Information

- Minimum Order Quantity

- 12 Pieces

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Main Export Market(s)

- Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Asia

- Main Domestic Market

- All India

About DIDW Centrifugal Fan 151 MM X 100 MM

DIDW Centrifugal Fan 151 MM X 100 MM

DIDW CENTRIFUGAL BLOWER

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

| OD X HT X ID | OD X HT | MM & INCH |

|

||

| 1 | ETIP 6 40 | 151 X 100 X 122 | 6 X 4 | 12.70 (1/2) & 15 MM | AL. / GI. |

Efficient HVAC Air Handling

Designed as a double inlet, double width centrifugal fan, this product excels in air handling for ventilation and HVAC systems. With its backward curved impeller and direct drive mechanism, it ensures consistent airflow and high efficiency across environments such as offices, factories, and air handling units.

Durable Construction & Safety

Manufactured from mild steel and coated for surface protection, the DIDW centrifugal fan offers long-lasting durability. The IP44 ingress protection safeguards the motor against dust and water splashes, making it suitable for industrial and commercial use in Indias varying climate conditions.

FAQs of DIDW Centrifugal Fan 151 MM X 100 MM:

Q: How is the DIDW Centrifugal Fan installed?

A: The fan is flange mounted, allowing for secure and stable installation in ventilation ducts, HVAC systems, or air handling units. Professional installation is recommended to ensure optimal performance and adherence to safety standards.Q: What are the usage applications for this centrifugal fan?

A: The DIDW Centrifugal Fan is ideal for ventilation, air handling units, and HVAC systems in commercial, industrial, and residential spaces, supporting air flow requirements between 300 and 900 m/h.Q: When should maintenance be performed on the fan?

A: Routine inspection and cleaning are recommended every six months, particularly checking for dust buildup or wear. Regular maintenance ensures continued high efficiency and extended operational lifespan.Q: Where is this centrifugal fan suitable for installation?

A: Suitable for indoor environments across India, including offices, factories, hospitals, and residential buildings, especially where horizontal air discharge and reliable ventilation are required.Q: What are the main benefits of the backward curved impeller design?

A: The backward curved impeller increases efficiency, reduces noise (to less than 70 dB), and minimizes the risk of clogging, resulting in smooth and reliable airflow even in challenging conditions.Q: How does the fans efficiency impact energy consumption?

A: Operating at up to 85% efficiency, the DIDW centrifugal fan reduces energy usage and operating costs, delivering consistent airflow while meeting ANSI/AMCA application standards.Q: What process is followed to ensure durability and safety of the fan?

A: The fan undergoes powder coating for surface protection and compliance with IP44 ingress protection, ensuring resistance to environmental factors such as dust and moisture. This process guarantees safety, durability, and longevity in operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in DIDW Centrifugal Fans Manufacturer in India Category

DIDW Centrifugal Fan 610 MM X 455 MM

Price 21000 INR

Minimum Order Quantity : 12 Pieces

Noise Level : < 85 dB

Weight : Approx. 180 kg

Voltage : 415 V

Usage & Applications : Industrial Ventilation, HVAC Systems, Air Handling Units, Dust Extraction

DIDW Centrifugal Fan 530 MM X 455 MM

Price 20000 INR

Minimum Order Quantity : 12 Pieces

Noise Level : <80 dB

Weight : Approx. 95 kg

Voltage : 415 V

Usage & Applications : Ventilation, Industrial Air Handling, HVAC, Exhaust System

DIDW Centrifugal Fan 230 MM X 203 MM

Price 1800 INR

Minimum Order Quantity : 12 Pieces

Noise Level : 70 dB (Approx)

Weight : 12 kg

Voltage : 230 V

Usage & Applications : Ventilation, Air Handling Units, Industrial HVAC Systems

DIDW Centrifugal Fan 230 MM X 228 MM

Price 2000 INR

Minimum Order Quantity : 12 Pieces

Noise Level : <72 dB(A)

Weight : Approx. 9.5 kg

Voltage : 220240 V AC

Usage & Applications : Ventilation, Air Handling Units, HVAC systems

Send Inquiry

Send Inquiry