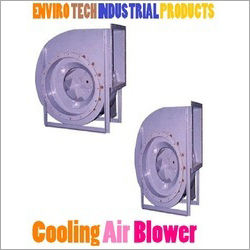

Cooling Air Blower

Cooling Air Blower Specification

- Efficiency

- Up to 98%

- Display Type

- Analog

- Measurement

- Standard

- Air Flow

- 1500-5000 m/h

- Automation Grade

- Semi-Automatic

- Instruments Type

- Industrial Blower

- Temperature

- Ambient to 60C

- Usage & Applications

- Industrial Cooling, Ventilation

- Orientation

- Horizontal

- Power Source

- Electric

- Product Type

- Cooling Air Blower

- Material

- Mild Steel

- Cooling System

- Air Cooled

- Noise Level

- Low

- Reactor Thickness

- Standard

- Processing Time

- Continuous

- Capacity

- High

- Voltage

- 220-240 V AC

- Weight

- Approx. 25-30 kg

- Dimension (L*W*H)

- 650 x 350 x 450 mm

- Surface

- Powder Coated

About Cooling Air Blower

Cooling Air Blower

We offer to the patrons an excellent range of Cooling Air Blower for HVAC which has been made using an outstanding quality of raw materials which have been sourced from renowned vendors in the market who are highly dependable and are popular in the industry for their quality products. Our products are highly hard-wearing and they are very robust in their construction. We offer these products to the patrons at very logical rates in the market.

Features:

-

Corrosion and abrasion resistant

-

Accurate

-

Longer life

-

Pocket friendly range

- Air Volume

- Air Pressure

- Motor H.P.

- Blower R.P.M.

- Operating Temp

- Drive Type

- Construction of Material (M.O.C.)

Application of Cooling Air Blowers HVAC:

Ceramic and Refractories Industries, Chemical Factories, Cement Plants, Crucible Furnaces, Furnaces like Oil, Gas, Cupola Furnaces, Flour Mills, Rolling Mills, Boilers, Textile Mills, Cattle Feed Plants, Pharmaceutical Industries, Fertilizer Industries, Plastic Machinery Plants, Hot Mix Plants, Iron and Steel Plants, Paper Industries, Process Industries, and many more.

Use of Cooling Air Blowers HVAC:

As Supply and Exhaust fans in Ventilation systems, In air handling units for air conditioning systems, In cold storage plants, For fume extraction in industrial plants, Industrial Blowers/Fans are widely used in Ventilation, Pollution Control, Fume Extraction, Dust collection, Induced Draft(ID Fans) and Forced Draft (F.D.Fans) for Boilers and Furnaces, suitable for various applications for Cooling, Humidification, Ventilation, Gas exhaust fans, Exhausters, fresh air supply, HVAC duties, Combustion for Burners, Recirculation of Fresh and United Air, etc.

also Manufacturer, Supplier, Export, of Different Blowers, like Single Inlet Single Width Centrifugal Backward/Forward Curve Blowers (SISW Blowers), Airfoil Blowers, DIDW Blowers, Centrifugal Blowers, Air Blowers, Exhaust Blowers, Combustion Blowers, High Pressure Blowers, Low Pressure Blowers, Forced Draft Blowers(F.D.Fans), Induced draft Blowers(I.D.Fans), and all types of Industrial Fans.

Cooling Air Blowers HVAC Features:

High efficiency, Low sound level, Compact Design, Large sizes can be dismantled, More Air with less HP, Easy in operation, Smooth in Running, Several versions available, etc.

Cooling Air Blowers HVAC are available in Three different Drives:

Direct Drive Cooling Air Blowers HVAC: All direct motor drive Cooling Air Blowers HVAC are supplied with suitable Electric motor with Fan cooling and also Flame Proof.

Other Information

- Pay Mode Terms: T/T (Bank Transfer)

Designed for Industrial Efficiency

Engineered for demanding industrial settings, this Cooling Air Blower boasts a high-performance centrifugal fan and aluminum blades to ensure reliable airflow. Its variable speed control and semi-automatic operation provide flexibility to meet diverse cooling requirements, making it suitable for continuous processing and high-capacity demands.

Durable Construction, Long-lasting Service

Crafted from powder-coated mild steel, the blower is built to withstand tough environments. The IP55 protection ensures resistance to dust and water, while Class F insulation enhances safety. With a projected service life of over five years, operators can trust in long-term stability and low maintenance.

Simple Installation & Versatile Application

Floor-mounted and horizontally oriented, the blower fits easily into industrial spaces. It supports cooling and ventilation in varied applications, from manufacturing plants to warehouses. The analog display aids monitoring, and installation is quick with standard-sized air outlets and electrical requirements.

FAQs of Cooling Air Blower:

Q: How is the Cooling Air Blower installed and operated?

A: The blower is floor-mounted for stability and requires a standard 220-240 V AC single-phase supply. With variable speed control and an analog display, operation is straightforward, supporting both manual adjustments and semi-automatic processes.Q: What are the main benefits of using this industrial air blower?

A: Key benefits include high-efficiency cooling (up to 98%), durability from powder-coated steel construction, reliable performance with IP55 protection, low noise levels, and the ability to handle continuous, heavy-duty applications with a long service life.Q: When is it recommended to use this air blower for maximum efficiency?

A: It is best utilized in ambient environments up to 60C where continuous cooling, ventilation, or air circulation is needed, such as in factories, warehouses, or production facilities with high heat loads.Q: Where can this centrifugal air blower be applied effectively?

A: This air blower is suitable for diverse industrial environments, including cooling machinery, ventilating large spaces, or controlling air quality in both manufacturing and processing plants.Q: What is the process for maintaining the blower for optimal service life?

A: Routine checks of the motor, ensuring the air outlet and blades remain clean, and periodic inspections of electrical connections are recommended. The powder-coated finish and IP55 protection simplify maintenance by resisting corrosion and dust ingress.Q: How does the blower ensure operator safety and durability?

A: The blower includes IP55 protection against dust and water, Class F electrical insulation, and a sturdy design with a powder-coated exterior, all contributing to safer operation and an extended, trouble-free service life.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Fans Manufacturers India Delhi Category

SISW Centrifugal Fan

Orientation : Horizontal

Surface : Polished/Standard Finish

Product Type : Centrifugal Fan

Usage & Applications : Industrial Ventilation and Cooling

Material : Metal

Noise Level : Low

Centrifugal Blower

Orientation : Horizontal

Surface : Smooth

Product Type : Centrifugal Blower

Usage & Applications : Ventilation air circulation industrial processes

Material : Durable materials like metal alloys

Noise Level : Low noise level

Commercial Blower

Orientation : Horizontal

Surface : Painted/Coated

Product Type : Industrial Blower

Usage & Applications : Use in cooling ventilation dust control industries

Material : Mild Steel

Noise Level : Low

Impellers Cast Iron

Orientation : Horizontal / Vertical as per application

Surface : Smooth, anticorrosive painted

Product Type : Impeller

Usage & Applications : Industrial pumps, water supply systems, chemical processing, irrigation, sewage treatment

Material : Cast Iron

Noise Level : Low

Send Inquiry

Send Inquiry