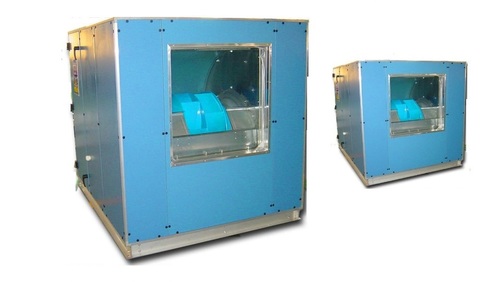

Cdif Direct Drive Cabinet Fans

Cdif Direct Drive Cabinet Fans Specification

- Orientation

- Horizontal / Vertical

- Sensor Type

- Optional airflow and pressure sensors

- Temperature

- -20C to +50C operational

- Efficiency

- High efficiency

- Display Type

- Analog / Optional Digital

- Power Source

- Electric

- Measurement

- Air pressure and volume

- Instruments Type

- Industrial Fan

- Automation Grade

- Automatic / Semi-automatic

- Air Flow

- Up to 50000 CMH

- Usage & Applications

- Ventilation, HVAC systems, Air circulation in industrial and commercial buildings

- Product Type

- Direct Drive Cabinet Fan

- Material

- Galvanized Steel / Mild Steel

- Cooling System

- Air

- Noise Level

- 65-80 dB

- Reactor Thickness

- 1.2 mm

- Processing Time

- Customizable as per requirement

- Capacity

- 2000-50000 m/h

- Voltage

- 380V / 415V

- Weight

- Varies by model (approx. 80350 kg)

- Dimension (L*W*H)

- Customized / Model specific

- Surface

- Powder coated or GI finish

Cdif Direct Drive Cabinet Fans Trade Information

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Cheque, Cash in Advance (CID), Cash Advance (CA)

- Packaging Details

- www.envirotechindustrialproductsdelhi.com

- Main Export Market(s)

- Australia, North America, Eastern Europe, Western Europe, Middle East, Africa, Central America, South America, Asia

- Main Domestic Market

- All India

About Cdif Direct Drive Cabinet Fans

- Cabinet manufactured in galvanised steel complete with inlet and outlet spigots and powder coating option is also available.

- Mounting brackets and access panel fitted as standard.

- All models have multi speed motor with selector switch.

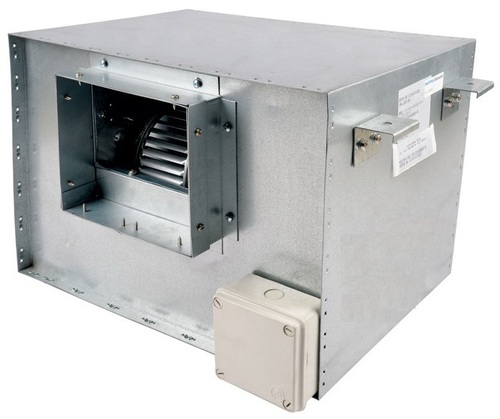

- High efficiency forward curved DIDW impeller with galvanised steel scroll.

- Squirrel cage induction motors with sealed for life bearing suitable for single phase electrical supply.

- Double skin models are available having GI outer skin with 25 mm glasswool wrapped in tissuepaper and covered with perforated GI sheet from inside.

- Filter fixing arrangement is a standard feature in all model while filter is an optional item.

- Cabinet fans with EC Motor are also available as option.

High-Efficiency and Versatility

Cdif Direct Drive Cabinet Fans offer high efficiency and exceptional versatility with customizable speed, mounting options, and dimensions. Their robust construction ensures durability and adaptability for diverse environments, from industrial plants to commercial complexes. The optional VFD control allows precise speed regulation, maximizing energy savings while meeting specific airflow requirements.

Customizable for Multiple Applications

Whether you need enhanced airflow for HVAC systems or general ventilation, these cabinet fans are designed to fit most use cases. Customizable capacity (2,000 to 50,000 m/h), dimensions, and processing times make them ideal for a variety of industries and settings, guaranteeing optimal air quality and circulation as per project requirements.

FAQs of Cdif Direct Drive Cabinet Fans:

Q: How does the Cdif Direct Drive Cabinet Fan improve ventilation efficiency?

A: The direct drive design, paired with backward or forward curved impellers, ensures efficient air movement with reduced energy loss. Variable fan speeds and optional VFD enable precise airflow control, optimizing ventilation for varying demands while minimizing operational costs.Q: What are the advantages of different mounting options for the cabinet fan?

A: Offering floor, duct, or wall mounting, these fans provide flexibility during installation to suit spatial constraints and airflow patterns. This versatility allows for optimal integration with existing HVAC or ventilation systems in industrial or commercial settings.Q: When should I choose a backward curved impeller over a forward curved one?

A: Backward curved impellers are ideal for high-pressure, energy-efficient operations, commonly used in larger ventilation projects. Forward curved impellers are suitable for applications that require lower pressure but higher airflow at lower noise levels. The choice depends on your specific air circulation needs.Q: Where are these cabinet fans most commonly utilized?

A: These cabinet fans find extensive application in industrial ventilation, HVAC systems, commercial building air circulation, and process cooling, providing reliable performance in factories, warehouses, malls, and office complexes.Q: What is the process for customizing a cabinet fan?

A: You can specify requirements such as airflow capacity, dimensions, mounting style, and motor brand during the consultation stage. The manufacturer then tailors the fan design, reactor thickness, and control options to align with your projects unique specifications and processing time needs.Q: How do these fans handle harsh operational environments?

A: Constructed from galvanized or powder-coated steel and equipped with IP54/IP55 motors, the fans are resilient against dust and moisture. They operate efficiently within -20C to +50C, making them suitable for Indias wide range of industrial and climatic conditions.Q: What benefits does the optional Variable Frequency Drive (VFD) provide?

A: A VFD enables adjustable fan speeds, improving energy efficiency by matching airflow output to real-time requirements. This leads to reduced electricity consumption, lower maintenance costs, and prolonged equipment lifespan.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Inline Fans Manufacturer Supplier Wholesaler Delhi Category

Inline Cabinet Fan Direct Drive DIDW Blower 500 CFM

Price 14000 INR

Minimum Order Quantity : 1 Pair

Material : GI Sheet / Galvanized Steel

Usage & Applications : Ventilation, Air Conditioning, Clean Rooms, Commercial Spaces

Voltage : 230 V

Cooling System : Other, Air Cooled

Double Skin Cabinet Inline Fan

Material : Galvanized Steel with Double Skin Panels

Usage & Applications : Ventilation, HVAC Ducting, Cleanroom, Commercial Spaces, Factories

Voltage : 220240 V AC, 50 Hz

Cooling System : Other, Air Cooled

Inline Fan With SISW Blower 1800 CFM

Price 20000 INR

Minimum Order Quantity : 1 Pair

Material : Mild Steel / Galvanized Steel

Usage & Applications : Ventilation, HVAC, Industrial Exhaust

Voltage : 415 V

Cooling System : Other, Air Cooled

Duct Inline Fan

Material : Galvanized Steel

Usage & Applications : Ventilation, HVAC, Commercial & Industrial Air Handling

Voltage : 220240 V

Cooling System : Air Cooling

Send Inquiry

Send Inquiry