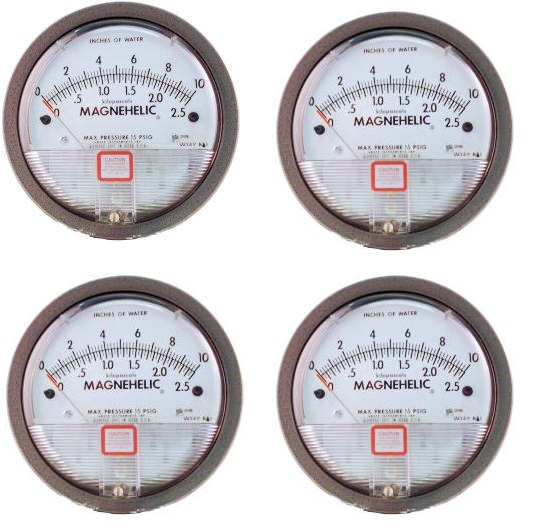

Analog DWYER Series 2000 Magnehelic Gauge In Salem Tamil Nadu

Analog DWYER Series 2000 Magnehelic Gauge In Salem Tamil Nadu Specification

- Thread

- 1/8 NPT

- Sensor Type

- Differential Pressure Sensor

- Seal Material

- Neoprene or silicone as per model

- Grade

- Industrial

- Bourdon Tube

- Not Applicable (uses diaphragm sensing element)

- Outer Size

- 4 inch (101.6 mm) diameter

- Display

- Analog

- Material

- Die-cast aluminum case, acrylic cover

- Dial Material

- Acrylic

- Pointer Material

- Plastic

- Processing Type

- Precision engineered

- Diameter

- 4 inch (approx. 101.6 mm)

- Glass Size

- Full size front transparent acrylic window

- Mount Type

- Surface/Circular/Panel Mounting

- Scale Range

- 0-60 Pa (various ranges available upon request)

- Accuracy

- 2% of full scale

- Finishing

- Matte finish

- Measure Pressure Of

- Air and compatible gases

- Accessories

- Two static pressure tips, two mounting screws, and installation instructions

Analog DWYER Series 2000 Magnehelic Gauge In Salem Tamil Nadu Trade Information

- Minimum Order Quantity

- 24 Pieces

- FOB Port

- Delhi

- Payment Terms

- Letter of Credit at Sight (Sight L/C), Cash on Delivery (COD), Letter of Credit (L/C), Telegraphic Transfer (T/T), Western Union, Paypal, Delivery Point (DP), Cash Advance (CA), Cash Against Delivery (CAD), Days after Acceptance (DA), Cash in Advance (CID), Cheque

- Main Export Market(s)

- Western Europe, Central America, Eastern Europe, Middle East, South America, Asia, North America, Australia, Africa

- Main Domestic Market

- Manipur, Dadra and Nagar Haveli, Himachal Pradesh, Andaman and Nicobar Islands, Nagaland, Pondicherry, Uttarakhand, Daman and Diu, Lakshadweep, Haryana, South India, East India, West India, Assam, Arunachal Pradesh, Bihar, Chandigarh, Delhi, Gujarat, Goa, Jammu and Kashmir, Jharkhand, Maharashtra, Mizoram, Meghalaya, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, West Bengal, Madhya Pradesh, Karnataka, North India, Andhra Pradesh, Kerala, Central India, Odisha, Chhattisgarh, All India

About Analog DWYER Series 2000 Magnehelic Gauge In Salem Tamil Nadu

Analog DWYER Series 2000 Magnehelic Gauge In Salem Tamil Nadu

- Overpressure - Protective rubber stopper will be blown out if rated pressure is up to about 50.8 inHg (172KPa).

- Process Connections - 1/8 INCH Female NPT duplicate high and low pressure taps - one pair side and one pair back

- Housing - Die cast aluminum case and bezel, with acrylic cover, Exterior finish is coated gray to withstand 168 Hour Salt Spray Corrosion Test

- Accuracy - Plus Minus 2 Preceding of full span at 70 21 3 Preceding on -0, and Plus Minus 4 Preceding on -00)

- Range -20 inHg-38 inHg (-68KPa-130KPa)(Special Specification also can be ordered.)

FEATURES

- OEM/ODM

- There Is No Need To Fill Liquid To Gauge.

- The Gauge Can Measure Positive Pressure, Negative Pressure And Differential Pressure.

- It Will Be Easy To Install And Measure In Different Ways Because Of Two Groups Of Ports Which Can Measure Positive And Negative Pressure.

- To Eliminate The Friction From The Movement Of Gear Wheel By The Mechanism Of Magnetic Magnet Feed.

- Exact And Stable Fixed Position Of Needle.

- The Gauge Has Great Antiknock Characteristics.

- There Are 81 Types Of Ranges. Minimum is 0-60 Pa And Maximum is 0-21-KPa.

Additional Information:

- Item Code: Analog-DWYER-Series-2000-Magnehelic-Gauge-Salem

- www.envirotechdelhi.com

- www.envirotechindia.co.in

- www.envirotechdelhi.in

Precise Differential Pressure Measurement

Engineered for accuracy and reliability, the Magnehelic Series 2000 Gauge utilizes a diaphragm sensing element to rapidly detect minute pressure changes. Its analog display allows for quick visual interpretation, making it a cornerstone tool in industrial air management and system optimization.

Built for Demanding Industrial Environments

Constructed with a textured die-cast aluminum case and a shatter-resistant acrylic cover, this gauge withstands harsh conditions. The external zero adjustment screw facilitates recalibration without dismantling, ensuring enduring precision even with frequent usage in varied settings.

Easy Installation and Versatile Mounting

Designed for flexibility, the Series 2000 can be mounted on surfaces, panels, or circular fixtures. Standard 1/8" NPT pressure taps and supplied accessories simplify the setup process, while comprehensive instructions further guide users through installation.

FAQ's of Analog DWYER Series 2000 Magnehelic Gauge In Salem Tamil Nadu:

Q: How do I install the DWYER Series 2000 Magnehelic Gauge?

A: To install, select a vertical mounting orientation and use the provided mounting screws and pressure tips. Connect the 1/8 inch NPT high and low pressure taps to your system. Follow the included installation instructions for surface, circular, or panel mounting as required.Q: What types of applications is this gauge suitable for?

A: The Series 2000 Magnehelic Gauge is ideal for HVAC system monitoring, air filter status checks, velocity measurement, and monitoring fan or blower pressures. It measures the pressure of air and compatible gases, making it a versatile tool in industrial and commercial environments.Q: When should the zero adjustment screw be used?

A: Use the external zero adjustment screw whenever the gauge needle fails to return to zero when disconnected from all pressure. Routine recalibration, especially after prolonged use or before critical measurements, ensures continued accuracy.Q: Where is this product available for purchase in Salem, Tamil Nadu?

A: The DWYER Series 2000 Magnehelic Gauge is available through authorized manufacturers, suppliers, traders, and wholesalers in Salem, Tamil Nadu, India. Contact local distributors or industrial equipment providers for stock and purchase details.Q: What is the process for maintaining the gauge?

A: Maintenance involves periodic inspection for leaks at fittings, cleaning the acrylic window with non-abrasive materials, and ensuring the zero point remains accurate. The robust design minimizes the need for frequent service, but regular checks are recommended for sustained accuracy.Q: Can the gauge handle overpressure situations?

A: Yes, the Series 2000 Magnehelic Gauge is engineered to be safe up to its maximum rated pressure of 172 kPa (2.5 psi). It includes built-in overpressure protection to help prevent damage in case of accidental overpressure.Q: What are the key benefits of using this analog gauge?

A: This gauge offers instantaneous mechanical response, reliable accuracy (2% of full scale), and straightforward visual readings. Its robust construction, simple installation, and compatibility with various mounting options make it an efficient choice for ongoing industrial monitoring.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Analog DWYER Series 2000 Magnehelic Differential Pressure Gauge Wholesalers India Delhi Category

Magnehelic Differential Pressure Gauge From Prabhani Industrial Area Maharashtra India

Price 5800 INR / Piece

Minimum Order Quantity : 1 Piece

Mount Type : Back

Pointer Material : Alloy

Material : Metal Alloy

Processing Type : Standard

Analog DWYER Series 2000 Magnehelic Differential Pressure Gauge Dealers For Noida Uttar Pradesh

Price 7500 INR / Piece

Minimum Order Quantity : 24 Pieces

Mount Type : Back

Pointer Material : Alloy

Material : Metal Alloy

Processing Type : Standard

Analog DWYER Series 2000 Magnehelic Differential Pressure Gauge Wholesaler For Chennai Tamil Nadu

Price 7500 INR / Piece

Minimum Order Quantity : 24 Pieces

Mount Type : Back

Pointer Material : Alloy

Material : Metal Alloy

Processing Type : Standard

Analog DWYER Series 2000 Magnehelic Differential Pressure Gauge For Chennai Tamil Nadu

Price 7500 INR / Piece

Minimum Order Quantity : 24 Pieces

Mount Type : Back

Pointer Material : Alloy

Material : Metal Alloy

Processing Type : Standard

Send Inquiry

Send Inquiry