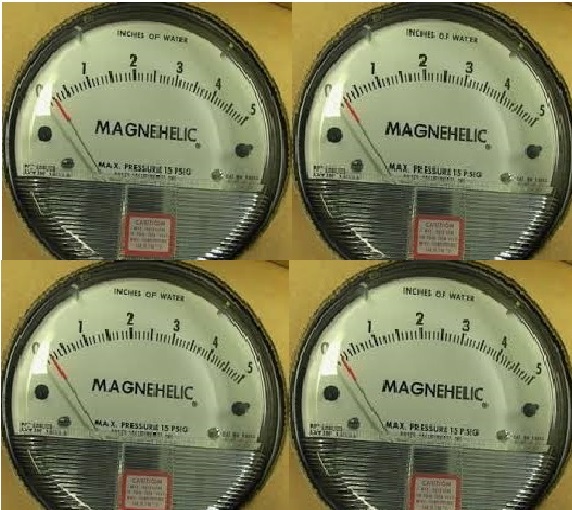

Analog DWYER Series 2000 Magnehelic Gauge In Noida Uttar Pradesh

MOQ : 24 Pieces

Analog DWYER Series 2000 Magnehelic Gauge In Noida Uttar Pradesh Specification

- Outer Size

- Standard (Refer Diagram)

- Seal Material

- Silicone / Buna-N

- Sensor Type

- Differential Pressure Sensor

- Display

- Analog

- Grade

- Industrial Grade

- Thread

- 1/8 NPT

- Material

- Die-cast Aluminum Case, Acrylic Cover

- Dial Material

- White Printed Aluminum

- Pointer Material

- Black Aluminum

- Processing Type

- Machined / Assembled

- Diameter

- Approx. 115 mm

- Glass Size

- Full Front Cover

- Mount Type

- Surface / Flush Mounting

- Scale Range

- 0-60 Pascals to 0-30 psi (Varied Ranges available)

- Accuracy

- 2% of Full Scale

- Finishing

- Powder Coated / Anodized

- Measure Pressure Of

- Air and Non-corrosive Gases

- Accessories

- Two Pressure Taps, Mounting Brackets, User Manual

Analog DWYER Series 2000 Magnehelic Gauge In Noida Uttar Pradesh Trade Information

- Minimum Order Quantity

- 24 Pieces

- Main Export Market(s)

- Western Europe, Central America, Middle East, South America, Asia, Eastern Europe, North America, Australia, Africa

- Main Domestic Market

- Dadra and Nagar Haveli, Himachal Pradesh, Andaman and Nicobar Islands, Uttarakhand, Daman and Diu, Lakshadweep, Haryana, South India, East India, West India, Assam, Arunachal Pradesh, Bihar, Chandigarh, Delhi, Gujarat, Goa, Jammu and Kashmir, Jharkhand, Karnataka, Maharashtra, Mizoram, Meghalaya, Manipur, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, Nagaland, Uttar Pradesh, Madhya Pradesh, North India, Andhra Pradesh, Kerala, Central India, Odisha, Chhattisgarh, All India

About Analog DWYER Series 2000 Magnehelic Gauge In Noida Uttar Pradesh

- Rated Pressure -20 inHg-30 inHg (-68-103KPa)

- Overpressure - Protective rubber stopper will be blown out if rated pressure is up to about 50.8 inHg (172KPa).

- Process Connections - 1/8 INCH Female NPT duplicate high and low pressure taps - one pair side and one pair back

- Housing - Die cast aluminum case and bezel, with acrylic cover, Exterior finish is coated gray to withstand 168 Hour Salt Spray Corrosion Test

- Accuracy - Plus Minus 2 Preceding of full span at 70 21 3 Preceding on -0, and Plus Minus 4 Preceding on -00)

- Range -20 inHg-38 inHg (-68KPa-130KPa)(Special Specification also can be ordered.)

FEATURES

- OEM/ODM

- There Is No Need To Fill Liquid To Gauge.

- The Gauge Can Measure Positive Pressure, Negative Pressure And Differential Pressure.

- It Will Be Easy To Install And Measure In Different Ways Because Of Two Groups Of Ports Which Can Measure Positive And Negative Pressure.

- To Eliminate The Friction From The Movement Of Gear Wheel By The Mechanism Of Magnetic Magnet Feed.

- Exact And Stable Fixed Position Of Needle.

- The Gauge Has Great Antiknock Characteristics.

- There Are 81 Types Of Ranges. Minimum is 0-60 Pa And Maximum is 0-21-KPa.

Additional Information:

- Item Code: Analog-DWYER-Series-2000-Magnehelic-Gauge-Noida-UP

- www.envirotechindustrialproducts.com

- www.envirotechindustrialproducts.in

- www.envirotechindustrialproduct.com

High Precision and Robust Construction

Engineered with a machined brass movement and a die-cast aluminum case, the Series 2000 Magnehelic Gauge provides durability and long-lasting performance. The acrylic cover and powder-coated or anodized finish ensure resistance to demanding environments. Its design minimizes wear and tear, making it ideal for continuous industrial use.

Versatile Pressure Measurement Applications

The Magnehelic Gauge is suitable for a broad range of uses, notably in HVAC systems, clean rooms, and filter monitoring. Thanks to differential pressure sensing and a standard thread size of 1/8 NPT, installation and adaptation to existing systems are straightforward. Its varied scale ranges accommodate both low-pressure and higher-pressure requirements.

User-Friendly Features and Accessories

This gauge features an external zero adjustment knob for easy calibration, ensuring ongoing accuracy. Accessories like pressure taps, mounting brackets, and a user manual simplify installation and operation. The clear, full-front analog display allows quick readings, and two mounting options-surface or flush-provide installation flexibility.

FAQ's of Analog DWYER Series 2000 Magnehelic Gauge In Noida Uttar Pradesh:

Q: How reliable is the DWYER Series 2000 Magnehelic Gauge for industrial applications?

A: Designed with industrial-grade materials like precision-engineered brass and a die-cast aluminum case, this gauge offers robust reliability. It delivers high accuracy (2% of full scale) and operates over a wide temperature range, making it well-suited for demanding environments such as HVAC systems and clean rooms.Q: What types of gases can be measured using this Magnehelic Gauge?

A: This gauge is specifically engineered to measure the differential pressure of air and non-corrosive gases, ensuring safe and accurate results in environments where chemical resistance is not critical.Q: When should the zero adjustment be performed on this device?

A: Zero adjustment via the external knob should be performed during installation or maintenance to compensate for any minor shifts in baseline pressure and maintain calibrated accuracy throughout the gauge's use.Q: Where is the Series 2000 Magnehelic Gauge most commonly installed?

A: This gauge is commonly mounted on equipment or walls in settings like HVAC units, clean rooms, and filtration systems. It supports both surface and flush mounting, providing flexibility depending on available installation space.Q: What accessories are included with the Magnehelic Gauge purchase?

A: Each unit comes complete with two pressure taps, mounting brackets, and a user manual, facilitating both installation and routine operation.Q: How is the Magnehelic Gauge used for HVAC or filter monitoring?

A: In HVAC and filtration applications, the gauge measures differential pressure across filters, indicating filter condition. By monitoring changes in pressure, users can schedule timely maintenance or filter changes to ensure system efficiency.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Analog DWYER Series 2000 Magnehelic Differential Pressure Gauge Wholesalers India Delhi Category

Magnehelic Differential Pressure Gauge From Prabhani Industrial Area Maharashtra India

Price 5800 INR / Piece

Minimum Order Quantity : 1 Piece

Display : Analog

Thread : NPT 1/8 inch

Color : WHITE/Black

Dial Material : Plastic

Analog DWYER Series 2000 Magnehelic Differential Pressure Gauge Wholesaler For Noida Uttar Pradesh

Price 7500 INR / Piece

Minimum Order Quantity : 24 Pieces

Display : NO

Thread : NPT 1/8 inch

Color : WHITE/Black

Dial Material : Plastic

Analog DWYER Series 2000 Magnehelic Differential Pressure Gauge For Chennai Tamil Nadu

Price 7500 INR / Piece

Minimum Order Quantity : 24 Pieces

Display : NO

Thread : NPT 1/8 inch

Color : WHITE/Black

Dial Material : Plastic

Analog DWYER Series 2000 Magnehelic Differential Pressure Gauge Distributor For Chennai Tamil Nadu

Price 7500 INR / Piece

Minimum Order Quantity : 24 Pieces

Display : NO

Thread : NPT 1/8 inch

Color : WHITE/Black

Dial Material : Plastic

Send Inquiry

Send Inquiry